Between harvest and consumption of fresh produce, about 20 to 40 percent of all product is wasted. To prevent produce from going to waste, preserving the quality, and minimizing losses are key goals during the production and handling processes. "The traditional techniques for evaluating quality are harmful, labor-intensive, and unsuitable for automation," says Hunter Weber with CID BioScience. "However, newly developed non-destructive technologies such as near-infrared spectroscopy (NIRS), have found many commercial uses." They are appropriate for assessing packed goods and can be used without sample preparation. NIRS is mainly utilized for precision farming and fruit maturity assessment in the preharvest stages.

Pre-harvest applications

Pre-harvest applications include maturity assessment, nutrition, and irrigation management, as well as identification of illnesses and pests. A maturity assessment helps farmers decide when to harvest their crops to get the best possible quality. Utilizing either internal or external characteristics such as soluble sugar concentration (SSC), dry matter (DM), firmness, total acidity (TA), or chlorophyll degradation, NIRS determines the maturity of the fruit.

When it comes to nutrition and irrigation management, with the use of portable and remote near-infrared sensors, researchers can precisely measure the water content of leaves, the essential macronutrients, and the fertility of the soil. This information can be used to advise farmers on the best practices for managing irrigation and fertilizer in fields to enhance crop growth, yield, and quality.

Of all biotic factors, illnesses are responsible for half of yield losses. Early identification of diseases, weeds, and pest stress is possible using remotely senses images based on NIRS. "These images evaluate changes in internal chemical composition before forming external damages, making it possible to respond quickly and avoid yield and quality loss."

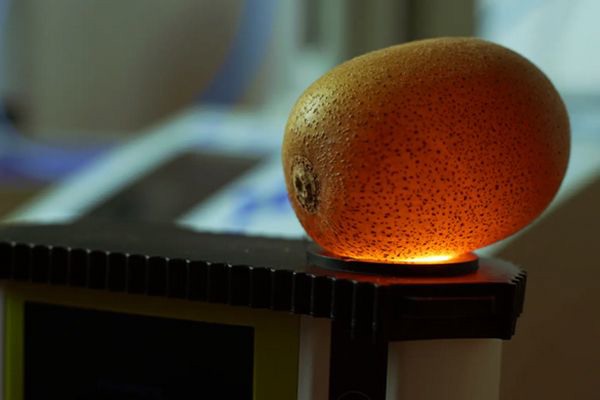

Quality Meters for melons and kiwi fruit.

Post-harvest applications

"Although both fixed and portable systems are available, chemometrics-assisted portable development, such as Felix Instruments' quality meters (F-750 and F-751s) for pre-harvest as well as post-harvest applications, is the new trend," Weber commented. "These Near-infrared spectroscopy meters are the most popular new non-destructive technology for applications before and after harvest," he added.

The F-750 quality meter has been developed for avocados, mangos, kiwis, and melons. For these fruit varieties, calibrated models are available. Mexico's National Institute for Forestry, Agriculture, and Livestock Research (INIFAP) has been extensively using the F-751 Mango Quality Meter since its inception. "The benefits of using this technology are the increase of up to two tons per hectare in at least 20 percent of the 30,000 hectares that are dedicated to export," says Dr. Jorge Osuna of INIFAP. Dr. Osuna and his team have helped provide the Mexican mango industry with the opportunity to expand its production efficiency. The team is applying the technology to Ataulfo, Tommy Atkins, Kent, and Keitt mangos, as well as other varieties.

In addition to mangos, avocados, kiwis, and melons, there is a list of fruits that the F-750 could be calibrated to measure and these fruits have been tested before. They include apples, grapes, citrus, tomatoes, berries, peaches, pears, cherries, and stone fruit.

For more information: Hunter Weber

Hunter Weber

CID BioScience / Felix Instruments

Tel: +1 (360) 833-8835 ext. 208

[email protected]

www.cid-inc.com