Following the COVID-19 pandemic, the frozen food retail market has witnessed a substantial increase in sales that is expected to maintain at a high level.

Food Safety has become even more crucial. New inquiries require “no hand touch” operation of processing lines. During stockpiling stage, freezer gondolas often were empty, and new deliveries were sold out fast.

"It is easy to understand as convenience is unbeatable, always at home, and to pick up and thaw what you need. Even if the pandemic will finish in a month like in China and South Korea, it is not very qualified to guess that we will have a future increase in retail in the time to come. North European processors discuss investing in new IQF line already for next season due to expected growth in retail. We live in a different world today compared to how it was three months ago."

If the Cold Chain is unbroken and modern equipment is used, quality is close to fresh (you can never compete with products direct picked from the garden but often compete with products bought at the fresh market as they often have day or days transportation time. Out of season, there is only frozen to choose.

Clearly, a winner in food safety is frozen food.

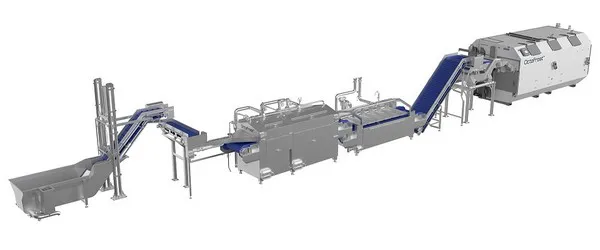

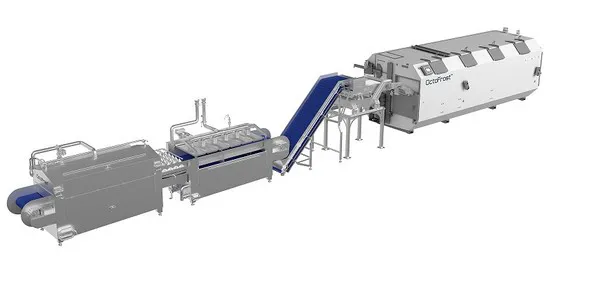

OctoFrost IQF Processing Lines

Green vegetables, many fruits, raw seafood are either fully blanched (+73Cto 85C where water or steam always is well over +73C) or flash blanched with hot water to kill surface bacteria. The heat treatment is followed by a swift chilling to capture texture and color on products. Water temperature in our rainfall chillers is 1-3 C, which is safe under the critical +6C you have in the fridge.Some berries and fruits cannot be blanched, where a light chlorine treatment before freezing is well proven and accepted.

Nearly all products can be randomly fed to the line and are spread with a shaker or water flumes, or tedder for leafy products. This also means significant labor-saving. A complete line only needs 2-3 operators.

OctoFrost IQF Processing Lines offer new challenging food safety business opportunities. The lines are designed for “no hand touch” after heat treatment.

"We design the complete processing line and have the control that there shall be no need for manual intervention. We can offer three complete food-safe processing lines."

Universal Vegetable Line

For most vegetables including herbs and spinach.

Asparagus Line

All belts are at the same level. Long and thin asparagus are transported through the freezer without any drop.

OctoFrost complete Shrimp Cooker, Chiller and Freezer Line

With Weighing Belt for even feeding Key feature is to have total control over temperatures to avoid overcooking and loss of

proteins.

For more information:

OctoFrost Group

Email: sales@octofrost.com

www.octofrost.com