The cost of labor is a common theme for most growers in North America. And that's if you can find the labor to begin with. It's therefore not surprising to see labor-saving initiatives being vigorously researched and implemented wherever possible. The usage of robotics and automated machinery is constantly rising and has become a profitable industry for equipment manufacturers.

"The need to reduce labor is the single biggest operational goal that our customers share with us," noted Brooks Lee of Durand-Wayland. "And, whether we are helping them reduce labor at the packing station or reducing forklift traffic, our goal is to put more money in their pocket. With hourly labor costs increasing annually and nearing $20 per hour in most places now, technology is the solution. Our technology providers, primarily Ellips, are well-suited to help our customers. Ellips’ outstanding grading accuracy reduces headcount from day one and reduces food waste."

Health and Safety an important factor

Aside from reducing the cost of labor, the use of automation lends itself to make the tasks easier to perform. Repetitive movement is one of the more common workplace hazards and has been shown to lead to injuries. Equipment manufacturers are keen to demonstrate the level of automation their machines can function with.

"I have always thought the industry could do much more to reduce repetitive motion injuries or potentially catastrophic accidents," Lee said. "The path to follow in this area is robotics and we have recently completed several outstanding palletizing and bin handling projects. Whether these projects were large and sophisticated or small and focused, our goal is to reduce headcount, reduce the chance of injury/accident and most of all, put money back in to our customer’s pockets."

Produce management

Another reason why some companies opt for automated processes is in relation to food management. Some of the latest grading machines have the ability to scan fruit and vegetables internally as well as externally, and then automatically direct each piece of fruit or vegetable accordingly. For example, many growers are turning to this technology to grade their produce automatically instead of by a worker who might only scan the external qualities. According to Lee, such technologies represent the 'biggest revolution' for the industry.

"The biggest revolution for fruit/vegetable machinery is the superiority of today’s cameras and LED light packages," he noted. "Ellips offers state-of-the-art hardware and with their always present outstanding programmers, customers enjoy an easy-to-learn and user-friendly interface. Whether it is grading blueberries at 45 pieces/lane/second or grading watermelons, customers can rest assured that they are operating the highest performing system in the industry."

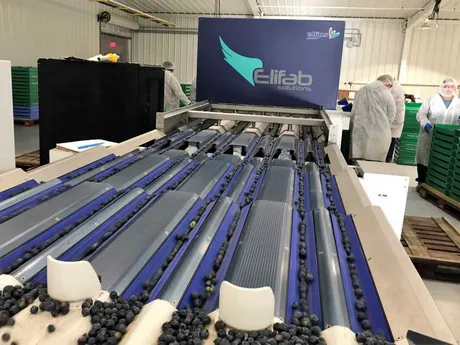

New blueberry sorter displayed at PMA Fresh Summit

In line with reducing food waste and optimizing production, Elifab have recently launched a new blueberry sorter which the company says can scan 45 pieces of fruit a second. The machine will be shown at PMA Fresh Summit this month, the first show in North America to display the Elifab blueberry sorter. Lee said Durand-Wayland, the distributor of the Elifab technology, will also have other equipment to discuss at PMA.

"We are very pleased to have several of our partner’s demo machines at PMA this year," he shared. "We will be highlighting Elifab’s outstanding blueberry sorter and Elisam’s rock solid Gran Torino sizer. Both machines feature Ellips’ Next Level Grading software. In addition, we will be featuring one of Burg’s bin handling items. Burg is an outstanding partner for all things bin handling."

He added that the PMA Fresh Summit provides a great opportunity to speak and interact with customers and peers without the distractions of the office. Additionally, it gives companies a chance to share news with their customers.

"PMA Fresh Summit is the event of the year to spend focused time with customers," he said. "The environment seems to allow them to avoid the typical barrage of phone calls and text messages so that they’re able to share their ideas and challenges while figuring out how we can help them convert on both. And since we have many customers in South and Central America, we are able to meet with them and share “what’s new” with Durand-Wayland."

For more information:

Brooks Lee

Durand-Wayland

Tel: +1 (706) 882-8161

[email protected]

www.durand-wayland.com