Reemoon has achieved a milestone in the Turkish market with the successful launch of its citrus sorting equipment in Mersin, Turkey. This marks Reemoon's first deployment of citrus sorting technology in the country, bringing solutions to the local industry.

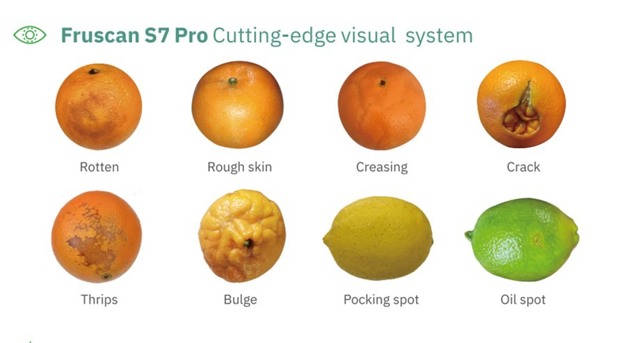

Nick, head of Reemoon's Turkish market, highlighted the advanced features of the equipment. "Our system integrates a cutting-edge electronic weighing mechanism and a high-precision visual inspection system, enabling accurate sorting based on weight, size, color, and surface defects." He emphasized that the equipment's visual inspection system is powered by Reemoon's Fruscan S7 Pro technology, which precisely detects a wide range of defects, including rotten, rough skin, cracks, thrips, pocking spots, and oil spots. Additionally, it allows for flexible parameter adjustments based on specific defect types and customer requirements, ensuring optimal sorting for every piece of citrus.

At the GOKALP packaging plant in Mersin, workers efficiently pack the sorted lemons. Bülent, the on-site engineering manager, stated, "Our equipment features six channels and processes over 20 tons of lemons per hour with exceptional sorting efficiency. Currently, it is used for four citrus varieties—lemons, oranges, tangerines, and grapefruits—handling up to 35,000 tons annually." This not only boosts productivity but also guarantees consistent product quality.

Beyond equipment performance, Reemoon places a strong emphasis on after-sales service. "From installation and commissioning to routine maintenance, our team works closely with GOKALP's quality and engineering managers to ensure seamless operation. We also provide comprehensive training and guidance on sorting parameter adjustments," said Nick. "Our goal is to help local customers efficiently manage shifting market demands through reliable after-sales support, enabling large-scale processing with ease."

To further enhance service quality, Reemoon has established its first after-sales service station in Mersin, ensuring prompt responses to customer needs and reinforcing local support. "This initiative not only improves service efficiency and strengthens customer confidence in our technology but also solidifies our position in the Turkish market."

Nick