Soilless strawberry irrigation has a new input thanks to the "IRRISENSE" Control Point, a system that revolutionises water management by turning substrate weight into an automation variable. By monitoring water loss in real-time through evapotranspiration, the system activates irrigation only when it is needed, ensuring efficiency, sustainability, and optimal productivity.

|  |

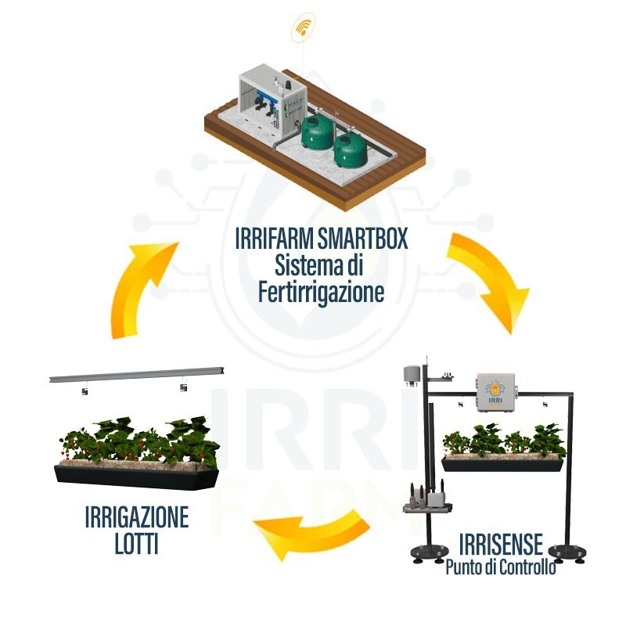

"We developed Irrisense to bring about a real change in the management of soilless irrigation," explains Bernardo Grieco, CEO of PanAgri. "The system no longer works on predefined schemes, but on actual data. Farmers set the initial conditions, and Irrisense autonomously detects the weight of the substrate and communicates with the Irrifarm Master to determine the exact moment when irrigation is needed."

The key element is the continuous sensing of substrate weight using load cell sensors, which allow the precise measurement of the water lost through evapotranspiration. This parameter is crucial in the cultivation of soilless strawberries, as too frequent irrigation can lead to root asphyxia, while an insufficient supply can quickly induce water stress and salt accumulation in the substrate, compromising yield and fruit quality.

"When a predefined threshold of weight loss is reached, Irrisense transmits the information to Master Irrifarm, the control centre that manages the entire system. Each variety is associated with a dedicated Irrisense Control Point, which monitors the specific conditions and transmits the data to the Master Irrifarm by collecting information from all the plots and deciding which irrigation valves to activate and for how long based on the pre-set parameters. This ensures a targeted water supply and avoids wastage in times of acute water scarcity.

"When a predefined threshold of weight loss is reached, Irrisense transmits the information to Master Irrifarm, the control centre that manages the entire system. Each variety is associated with a dedicated Irrisense Control Point, which monitors the specific conditions and transmits the data to the Master Irrifarm by collecting information from all the plots and deciding which irrigation valves to activate and for how long based on the pre-set parameters. This ensures a targeted water supply and avoids wastage in times of acute water scarcity.

Thanks to this approach, the entire system works dynamically: each plot receives water and nutrients only when they are needed, without depending on fixed irrigation schedules that do not take into account environmental variations and the physiological needs of plants.

"The system, designed and developed in our laboratories, was perfected thanks to the direct collaboration with producers and, in particular, with the Vincenzo Sabato farm in Scanzano Jonico (Matera), which contributed its experience to testing and optimising its functionality, ensuring a high-performance product in line with the real operational needs in the field," adds the CEO.

"The use of weight as a decision-making parameter represents a quantum leap. It is no longer farmers who have to schedule fixed irrigations, but it is the system itself that decides when and how much to irrigate based on the data collected. Thanks to this adaptive water management model, the system can drastically reduce water consumption, optimise root uptake and improve fertigation efficiency.

Irrisense is designed to operate in complete energy autonomy. Powered by a 20W solar panel with rechargeable batteries, it can be installed anywhere without the need for electrical connections or complex infrastructure.

"We are talking about a system that goes beyond simple monitoring. Irrisense is a true Decision Support System that optimises the management of fertigation, thereby increasing productivity and minimising waste. It is a technology at the service of plants, a new way of interpreting precision agriculture."

A sensor ecosystem for precision irrigation

Integration with other sensors allows Irrisense to further refine water and nutrient management:

- Weight sensors with load cells: they measure the real-time weight loss of the substrate by evapotranspiration, determining the exact moment when irrigation is needed;

- pH sensors: they constantly monitor the acidity level of the nutrient solution, adjusting fertiliser dosage to maintain an optimal balance;

- EC (Electroconductivity) sensors: they monitor the concentration of salts in the nutrient solution, making sure that plants receive the correct amount of nutrients;

- IN/OUT drainage sensors: they analyse the amount of water drained from the substrate, optimising the ratio between irrigation and water uptake;

- Air temperature and humidity sensor: it monitors environmental climatic conditions to avoid stress to the crop and allow targeted adjustments;

- Substrate salinity, temperature, and humidity sensor: it measures substrate water content and salinity level, preventing he accumulation of salts harmful to roots;

- Solar radiation sensor: it measures light intensity to adapt irrigation according to the plant's energy needs, ensuring the best balance between light, growth, and water uptake.

![]() For more information:

For more information:

Pan Agri Srl

Via degli artigiani, snc

75020 Scanzano Jonico (Matera)

+39 0835 952321

info@irrifarm.it

www.panagri.it