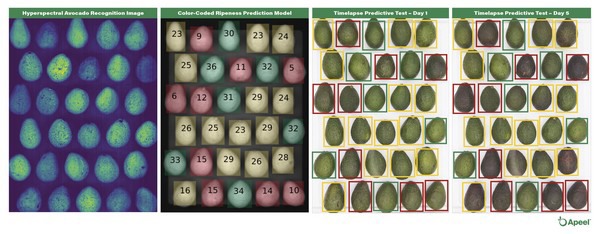

Apeel announced its acquisition of ImpactVision for an undisclosed amount. ImpactVision’s hyperspectral imaging technology is soon to be integrated into Apeel application systems at supplier locations around the world —adding a new layer of insights to help fresh food suppliers and retailers further reduce food waste. Apeel’s new imaging technology enables suppliers to see inside and understand the interior quality of fresh produce by collecting quantifiable data on stage of ripeness, freshness, nutritional density, and other indicators of quality. This marks Apeel’s first acquisition and a major step toward quantifying and digitizing produce quality data, with the goal of democratizing this new information for the benefit of Apeel’s partners and the global food system as a whole.

“Our journey began with Apeel’s plant-based protection -an invisible ‘peel’ that addresses the challenge of global food waste by bringing more time to fresh produce before it spoils. Now, we’re expanding our technology to bring to light the previously invisible characteristics of produce, including internal quality, phytonutrient content, and environmental impact,” said James Rogers, CEO of Apeel. “Using the insights enabled by Apeel’s imaging technology, our partners will effectively be able to ‘see’ inside of every fruit and vegetable, quantifying quality as never before, so that the distribution of fresh food can be optimized. For our partners, this will mean less waste and an immediate bottom-line improvement."

Apeel imaging technology. Click on photo to enlarge.

Apeel imaging technology. Click on photo to enlarge.

Apeel’s plant-based protection that doubles the shelf life of produce is currently applied to fruits and vegetables via application systems throughout packing houses and distribution centers across North America, South America and Europe. Apeel’s new imaging technology will be added to these systems to collect data-rich images as produce travels along packing house conveyance lines. Acquired images will then be processed through machine learning models that can identify unique visual cues that relate to freshness, degree of maturity, phytonutrient content, and other aspects of fruit quality.

"ImpactVision's technology can predict internal quality of food products from hyperspectral images. When this ability to 'see beyond the borders of human vision' is combined with Apeel's shelf-life extension technology, the potential to fundamentally transform produce supply chains to reduce post-harvest loss, optimize distribution and lengthen shelf-life is enormous,” said Abi Ramanan, Founder of ImpactVision.

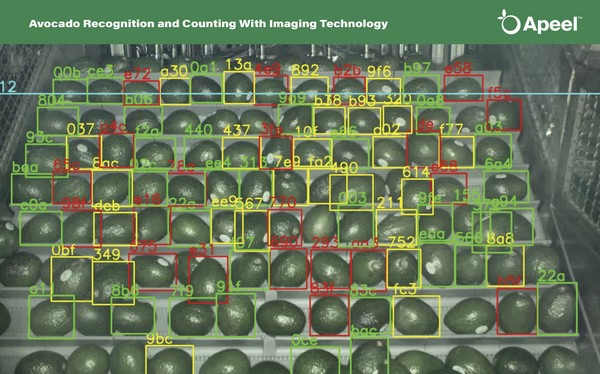

Avocado imaging.

Avocado imaging.

With Apeel’s continued expansion into new produce categories and geographies, the company is poised to capture category-wide datasets across a previously fractured and data-poor landscape, which in turn will help shape new efficiencies that span across global fresh fruit and vegetable supply chains.

For example, suppliers can now know the exact ripening window for each piece of fruit to then sort and ship to geographical locations that will ensure retailers are getting the highest quality produce. Today, Apeel has 30 supplier integrations on three continents with plans to double that number by the end of 2021.

For more information:

For more information:

Nadia Jamshidi

Apeel

Tel: 408-859-6052

nadia@goodnature.ventures

www.apeel.com