Carrots are a great vegetable. They’re healthy, taste good, have a crunchy bite and an attractive colour that contrasts nicely with other vegetables. But it’s not all that easy to retain that bright orange colour after peeling.

The difference between abrasive peeling and knife peeling

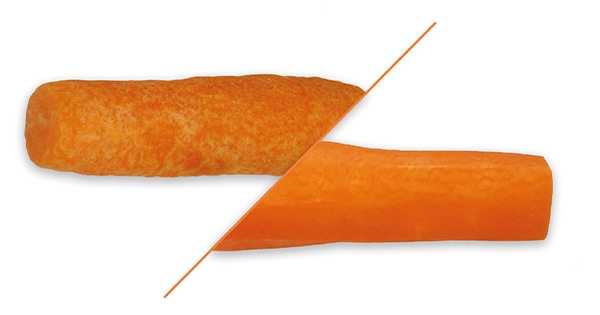

We’re all familiar with the whitening of the surface area of abrasive-peeled carrots. Consumers who see this wrongly assume that the product is mouldy, even though there’s nothing wrong with its microbiology. What’s going on here? The scraping process severely damages the carrot’s cell structure and leaves its surface area covered in torn cell walls.

Oxygen and light can now access the carotenoids, which leads to oxidation and thus to the loss of colour. The cell wall remnants turn white and the bright orange colour disappears.

This can be avoided by using a knife peeling instead of an abrasive peeling method. In knife peeling, the knives cut through the cell walls and leave an open structure without residues of damaged cell walls. The underlying cells remain intact and, because they aren’t exposed to oxygen, the carotenoids practically don’t oxidate and the colour is retained. A strong colour difference can be observed between carrots that have been peeled through knife peeling methods and abrasive peeling ones, within 24 hours.

Impact on microbiology

During abrasive peeling, some scraping waste remains on the carborundum rolls or discs used for scraping. The friction warms this waste and creates a breeding ground for microorganisms. These organisms come into contact with each subsequent carrot that is scraped, which leads to cross-contamination. When peeling with knives, on the other hand, the product and peel are separated by the knife such that cross-contamination doesn’t occur.

Knife peeling requires less energy. This means that the product’s surface is warmed to a lesser degree. With abrasive peeling the surface of the product heats up by 6 to 8°C; knife peeling prevents this. Another important advantage is that because the cell structures remain open after peeling with a knife, the remaining cell moisture is easy to rinse off such that it doesn’t form a breeding ground for micro-organisms.

Sormac’s peeling solutions

In addition to its abrasive peeling machines, Sormac offers various knife peeling solutions. On top of the above advantages, these knife peeling solutions have a favourable waste percentage of less than 20%. The knife peeler KP-60 is ideal for peeling carrots at a capacity of up to 4,500 pieces per hour. Combined with a PVW stepflow singulator and a carrot topper and piece-cutter WOS-1A, this is a versatile line already used by dozens of companies around the world. For higher capacity needs, the knife peeler UP-8000 offers a solution. This machine reaches a capacity of up to 8,000 carrots per hour. It, too, can be combined with a PVW step- ow singulator and a carrot topper and piece-cutter WOS-1A.

Peeling with a green twist

For special needs Sormac offers the knife peeler KWS, which peels carrots with a diameter of 10 to 45 mm whilst leaving the foliage intact. The result is an attractive combination of orange and green.

For more information:

Sormac B.V.

Tel: +31 [0]77 351 84 44

Email: [email protected]

www.sormac.nl