Although environmental sustainability is at the heart of agriculture and horticulture, the economic dimension, which is at the basis of the investments made to produce food, is often overlooked. However, it is possible to combine the two aspects and an example of this is represented by the efforts of the Agriplast company, which aims to respect not only nature but also the income of farmers, based on crop protection. And it is innovation, as always, that is at the basis of improvements in every process. This is why the Powerlux PNP cover sheet was developed.

Agriplast's plant

Agriplast's plant

"Protecting certain types of outdoor crops during the coldest months o f the year is essential for optimal crop success and for producing yields. One of the most widely used products for this purpose is non-woven fabric, or TNT, a fabric of filaments, usually of polypropylene (PP). These are arranged randomly, hence the name non-woven fabric," said Emanuele Garrasi, director of Agriplast (in the photo).

f the year is essential for optimal crop success and for producing yields. One of the most widely used products for this purpose is non-woven fabric, or TNT, a fabric of filaments, usually of polypropylene (PP). These are arranged randomly, hence the name non-woven fabric," said Emanuele Garrasi, director of Agriplast (in the photo).

"TNT is placed directly on the plants or laid on arches to cover the entire row. Thanks to its thermal and ventilation performance, it is able to create a microclimate that allows good development of the crop, despite cold temperatures. This type of protection is also water permeable, allowing the crop to be irrigated."

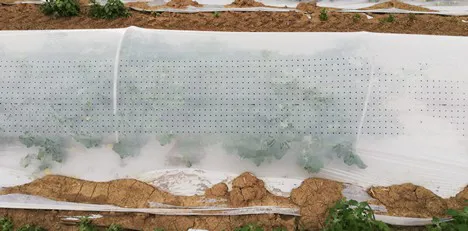

Photo above: Powerlux PNP, a perforated fabric 13 microns thick, light and resistant. Photo below: the less performing TNT.

Photo above: Powerlux PNP, a perforated fabric 13 microns thick, light and resistant. Photo below: the less performing TNT.

"As a producer of plastic films for agriculture and horticulture, we can offer an alternative to the classic TNT after much research and analysis. This is Powerlux PNP, a polyethylene fabric only 13 microns thick, with a special perforation system. The holes, in combination with the very high light transmission (about 83%), ensure the proper exchange of heat and moisture between the crop underneath and the outside air, creating a balanced microclimate that allows the proper development of the crop. The size of the holes is designed to allow water to pass through and for beneficial insects to get to them as well."

"Powerlux PNP not only has a weight per square meter that is on average 30% lower than that of TNT, but also reduces the amount of material that ends up on the market, and consequently, in the environment. Powerlux PNP is 100% recyclable, so it can be disposed of after the growth cycle without any problems, which helps to minimize the carbon footprint required to produce a given reference."

For more information:![]()

Emanuele Garrasi

Agriplast SPA

Via Filippo Bonetta 35

97109 - Vittoria (RG) - Italy

+39 0932 997211

enrico.garrasi@agriplast.com

www.agriplast.com