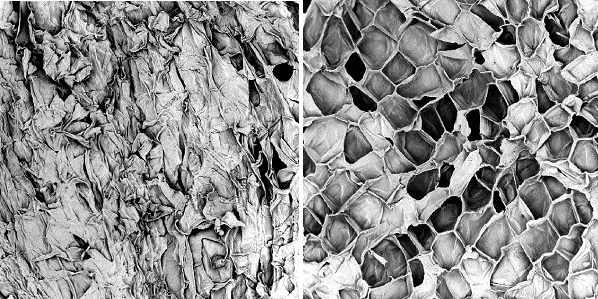

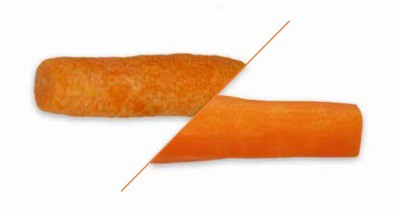

When you scrape (peel abrasively) carrots, their exterior turns white after a while. People mistakenly think the product is moldy. Scraping damages the carrot's cell structure; the cell walls are torn apart, as it were, and stick to the carrot's exterior. Oxygen and light then reach the carotenoids, and oxidation occurs, leading to color loss. The remnants of the cell walls turn white, and the carrots are no longer their distinctive bright orange.

microscopic view, left: scraped; right: peeled

There is a way to prevent this - peeling. Knives are used to slice through the cell walls, leaving an open structure with no left-over, damaged cell walls. The underlying cells remain intact, and oxygen cannot reach them. So, there is little to no oxidation of the carotenoids, and the color is preserved. Within 24 hours, there is a clear difference in color between carrots that have been peeled versus scraped.

During scraping, these bits of carrot peel remain behind on the peeling machine's carborundum rollers or discs. Friction heats this debris, creating the perfect breeding ground for microorganisms. These then come into contact with each subsequent carrot that is peeled: obvious cross-contamination. In contrast, during peeling, the product and peel are separated, so there is no cross-contamination.

Peeling with knives also requires less energy. That means the product surface does not get so hot. During scraping, the temperature on the exterior of the carrots rises by 6 to 8°C. Not so, with peeling. Another, not unimportant advantage: the open cell structure after peeling means you can easily rinse the remaining cell liquid away, and so microorganisms cannot multiply. And aside from all these benefits, peeling causes 20% less waste.

A Sormac carrot peeling machine

However, it costs much less to scrape carrots; peeling them is almost always more expensive. "Sormac has carrot peeling machines for different capacities," says the Dutch company's Roy Lemmen. "There are batch peelers that can do up to 20kg batches. Up to roller scrapers with a capacity of up to 6,000 kg per hour (depending on the peeling percentage and use). The revolver scraper is a great middle-of-the-way solution. It can process up to 700 kg per hour."

"The KP-60 peeler is great for capacities of up to 4,500 pieces per hour. For higher capacities, there's the UP-8000 peeler. You can do as many as 8,000 carrots per hour with it. For something very special, there's the KWS peeler that peels carrots with a diameter of 10 to 45 mm, leaving the foliage intact. That results in an attractive orange/green combination," he concludes.

Sormac B.V.

Sormac B.V.

Huiskensstraat 68

5916 PN Venlo

+31 [0]77 351 84 44

[email protected]

www.sormac.nl