Just months away from celebrating its 75th birthday, a leading Australian packaging and machinery solutions company has seen a lot of changing trends across the fresh produce industry.

edp australia pty ltd is a second-generation Australian family business, based in Victoria's Goulburn Valley and General Manager Ray Thrum says it was originally a manufacturing company, but the company has expanded significantly along with advances in technology in the past 30 years and has developed some international business partnerships. Now there are five divisions: packaging, grading and handling, palletising, orchard equipment and consumables.

"We now import the technology, and we can provide turnkey project solutions for customers," he explained. "Our reach is significant, and on our website, we have around 60 pages of the different things we do. Our partners have provided us with diversity in the products that we can offer. We also have a service department as you need the backup when machines break down, which is inevitable. One of the key strengths of this company over 75 years has been staff retention, with many staff members racking up more than 30 years’ service. So, customers who bought a machine 20 years ago, will still get the same team member to help them.

"That consistency and knowing our machines inside and out is a huge advantage. What Australian customers want is someone to project manage for them, not have four or five companies with their own different equipment. Another thing is we are big on Australian manufacturing. For example, with the current world situation, getting stuff from Europe is a nightmare, taking 12 months for machines to arrive. Customers can't wait that long so are turning to Australian companies to help and we have had an increase in enquiries."

Photo: Automatic bag and box palletizing line

The company has clients in every state and territory in Australia, across a large part of the fresh produce sector, including onions, potatoes, carrots, nuts and the full range of citrus. But edp can also work to a customers’ needs with other fruit and vegetable lines by modifying the machinery, with the exception of the softer items.

Photo: Grading Line Machine

Another area of the business that is growing is the "consumables" arm, and Business Manager of Retail Packaging Robert Marsters explains that edp launched polybags and net bags into the Australian market, and that division now makes up a third of the company's sales. He added that a big trend across the packaging industry is that retailers and consumers are demanding products become more environmentally friendly, which has also become a priority for edp.

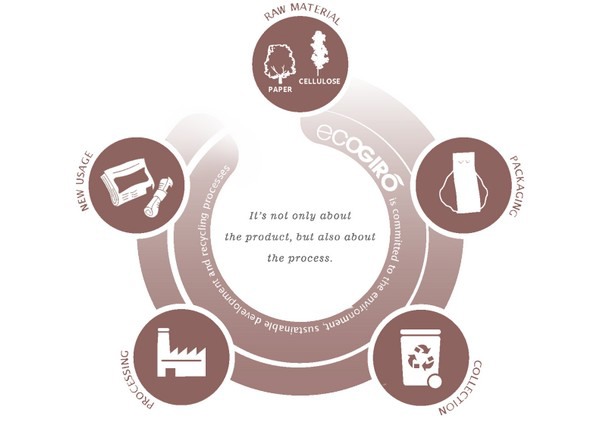

"You sell a machine initially, but consumables sales and packaging material direction are ongoing," Mr Marsters said. "With the focus being on sustainability, and the need for packaging to be compostable, recyclable or reusable moving into the future, we are lucky that all of our synthetic packaging is recyclable through the REDcycle program. We also have a range of fully compostable bags in that you just put them in your green waste bin. (Our international partners) Giro has just released a 100 per cent cellulose fully welded Ultrabag, Girbaggers first plastic-free packaging and I believe you dispose of the complete Ultrabag into the cardboard/paper recyclable bin.

"Technologically, it's a new, eco-friendly natural-looking, feeling product. It is paper film lined with heat-sensitive adhesive that activates when applying heat to bond the paper film with a 100% cellulose net. Both net and film are cellulosic origin materials with FSC certification (AEN-COC-000401). I think 'wow, it's such a great advancement in technology'. So, we have all those options. It is mainly on the back of European countries taking the lead to reduce their plastic. Environmentally friendly packaging is more expensive, but if you manufacture more the cheaper products become."

Photo: Cellulose Flow Chart

edp manufactures a range of different automation machinery for pack sheds, including bin tippers, hoppers, inspection tables, conveyors, elevators, rotary tables, catwalks, mechanical sizing, washing units, Electrobaggers, crate and box fillers - and has recently purchased a Leica BLK360 laser scanning cameras to provide 3D images remotely, of the client’s facility, to help construct these items.

The company has also recently released a new and exciting range of Specialist Automatic box and RPC/ tray Palletising machines onto the Australian Market. Mr Thrum says these machines have the potential to increase productivity for fruit and vegetable producers significantly.

"Labour is a big problem in Australia at the moment," he said. "I think it will remain a problem with COVID-19 around the world and people being unwilling to travel. So, I think that businesses, and family businesses, in particular, are looking for that automation to help minimise labour costs. They also look for a payback on these machines; it's one thing to invest in them but these machines pay back very well. So far, we are seeing the payback on these machines as soon as 18 months to three years, depending on each customer's volumes and what produce goes through the line. That is a good outcome for them when they are reducing labour, so we have got some really good sales in that area, as they are in high demand."

Photo: Knitted netting bags

Mr Thrum also added that one of the core company values is giving back to the industry, and is a strategic partner of Citrus Australia and AUSVEG, as well as being part of the original foundation of PMA Australia-New Zealand.

edp celebrates 75 years of operations in July.

For more information

For more information

Robert Marsters

edp Australia

Phone: +61 3 5820 5337

sales@edp.com.au

www.edp.com.au