Data analytics are becoming a must when shipping produce, it is essential for exporters to be able to track their containers and monitor handling conditions through the supply chain.

Tracknact has been offering an analytics platform to companies for two years, the data is taken from on-board trackers and can alert exporters in real-time when the cold chain is broken, vital when shipping temperature-sensitive products.

“As well as real-time temperature monitoring, we can also access historical shipment data for our clients, where they can compare quality and relevant factors from season to season,” explains Thomas McDade CEO and founder of Tracknact. “Using Tives latest technology bluetooth beacons has been a game changer opening up the industry as they vastly decrease the price and are increasing utilisation of multiple loggers per trip.”’

Thomas and the team at Tracknact worked with The Queensland Department of Agriculture and Fisheries on the Service Supply Chain Project and have worked with Manbulloo, a mango exporter based in Australia. They helped Manbulloo reduce the average arrival temperature in Asian markets by 4 degrees C and added an additional 2.4 days of shelf life. They are also active in the livestock and pharmaceutical industries.

Manbulloo was using an older technology to monitor temperature - USB data loggers. But the loggers had to be collected at the end of the trip and plugged into a PC for the data to be accessed. The success rate for retrieving USB loggers was less than 50%. Even when the loggers were retrieved, they couldn’t intervene during the shipment and only found that something had gone wrong after the fact.

Manbulloo was using an older technology to monitor temperature - USB data loggers. But the loggers had to be collected at the end of the trip and plugged into a PC for the data to be accessed. The success rate for retrieving USB loggers was less than 50%. Even when the loggers were retrieved, they couldn’t intervene during the shipment and only found that something had gone wrong after the fact.

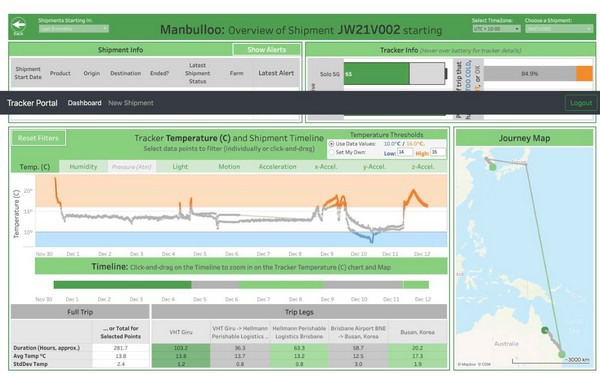

"Manbulloo’s ideal solution was a single dashboard, where we could set up the loggers with a high level of customisation (logger ID, batch codes, steps in the chain, optimum temperature ranges and so on), and access all data in real time, regardless of when it was captured and what logger brand was used," said Marie Piccone, Managing Director, Manbulloo Ltd.

"That’s where Tracknact came in. The software was developed so Manbulloo could track and record time x temperature conditions during packing and transport through the chain, and during storage and ripening by our chain partners.

"Now, we can open one dashboard and see the time x temperature conditions for all shipments — whether in real time or as a historical shipment."

“We can do the same as the data collection people with data loggers but we can also take the data produced by loggers from companies such as Tive and Emerson and provide it to customers," explains Thomas. "We can switch between data loggers without losing any historical information for our clients. As well as providing the real-time info during shipping we are working with Meat and Livestock Australia and can also tell our clients what the shelf life is on arrival and provide an end of trip report for the retailers and producers.”

All of these services can help eliminate waste and reduce claims for the grower/ exporter, the data and analytics can also be used to benchmark each part of the supply chain to find insights into the supply chain and compare technology.

For more information:

For more information:

Thomas McDade

Tracknact

[email protected]

www.tracknact.com