"I love blueberries," begins Barry Bondt. "It gives me great joy to see these three machines running at full tilt, perfectly sorting and packaging these berries."

This Dutch business owner is having a great time. Last summer, IQ Packing opened a new packing plant - fully equipped for packing and repacking blueberries - in R&M Forwarding's new warehouse at Dutch Fresh Port.

This is the third location for IQ Packing, a packaging company begun by Barry's father, Rob, in 1999. Its 'neighbor', Carsol Europe, which specializes in growing blueberries in South America and Europe, requested this extra branch. These two companies jointly began this new packaging company.

The berries, both conventional and organic, are packaged from 125 to 750g in all kinds of containers like punnets, with or without lids, shakers, and buckets.

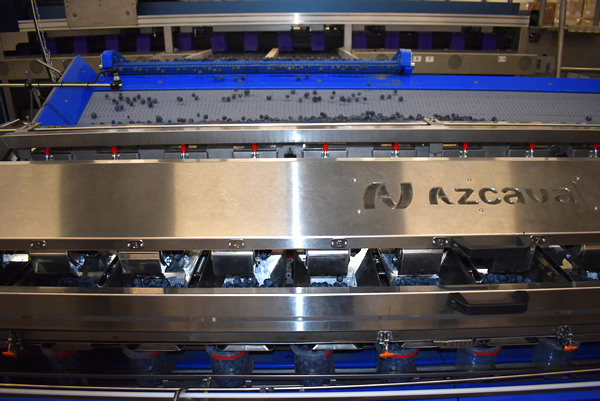

IQ Packing employs between 40 and 45 people and has three blueberry sorting machines (from Elifab, Kato, and Tomra). It can thus do many European customers' berry sorting and packaging for them. The machines are specially designed to deliver blueberries or cherries in bulk and then sort and package them in any desired packaging. "We can process 6,000 to 7,000 kg of berries per hour here," Barry says.

With Carsol Europe's supply of blueberries, IQ Packing can do great things in the overseas season. However, the company has facilities for grading and packing for other soft fruit producers too. "Think, for example, of Moroccan or Eastern European growers who want to be close to the European market and want to be able to switch quickly with packaging. We can provide these services perfectly from this new 3,000+ m2 building in a top location."

"We use top-of-the-range berry sorters. The Elifab grader, for example, offers never-before-seen possibilities. It can sort by color, firmness, and size to exact client specifications," explains Barry. "But an optical sorter cannot perform miracles. It can do great things, but it can't transform a bad batch of berries into a better one."

IQ Packing has no problem getting staff. "The berry season, fortunately, peaks opposite to that of the grape and citrus season. With blueberries, we'd already built up the needed expertise at our other plant, which we can build on here. We want to find a year-round process and, if necessary, will happily invest in further machinery expansion," Barry concludes.

Excess paper and plastic are shredded separately.

For more information:

For more information:

Barry Bondt

IQ Packing Barendrecht

110 Peterselieweg

2988 DH, Ridderkerk, NL

Mob: +31 (0) 630 368 853

Email: [email protected]

Website: www.iq-packing.nl