Clusters of snow-white velvet shank mushrooms, or Flammulina velutipes, are moving on the packing line. After being sorted and packed, they are put into boxes and sent to all parts of the country by tight cold-chain logistics.

These velvet shank mushrooms from Dezhou city were successfully promoted to be a flagship product from Shandong Province and are now part of the "Haopin Shandong" brand. Shandong is a large province in the East of China, known for its agriculture and horticulture production.

In the photo above is Shandong Kangrui Edible Mushroom Technology Co., Ltd. The company is located in the Edible Mushroom Industrial Park of Dahuang Township, Qihe County, Dezhou City, Shandong Province.

As soon as you enter the gate of Kangrui, you will be greeted by rows of neatly standardized mushroom cultivation workshops. Scientific factory planning, advanced bottle-making equipment, highly mechanized production facilities, a precise liquid bacteria inoculation line, an intelligent constant temperature mushroom incubation room, an automated packaging line, and 24-hour cold chain logistics - all of this shows Rui's capacity as an advanced mushroom cultivation base.

Jiang Guobin inspects on-side machinery

Jiang Guobin is the manager of the production department of Shandong Kangrui Edible Mushroom Technology Co., Ltd. He is originally from Taiwan but moved to Jiangsu Province more than ten years ago when he followed a Taiwanese company to start a business over there. Eventually, he married in Jiangsu and remained. He settled in Jiangsu and has since been engaged in the edible mushroom production industry.

During his business dealings, he met Zhang Hanbing, general manager of Shandong Kangrui Edible Mushroom Technology Co., Ltd., and joined Kangrui at the end of 2022 at the invitation of Mr. Zhang. Although he has only joined the company recently, with years of work experience and careful research, Jiang Guobin quickly mastered the production process of the company's mushroom cultivation base and began to optimize the production process and procedures.

"Look, these mushroom stalks are moderate in thickness, full in shape, and white in color, which shows that the quality of the velvet shank mushrooms is very good!" celebrated Jiang Guobin.

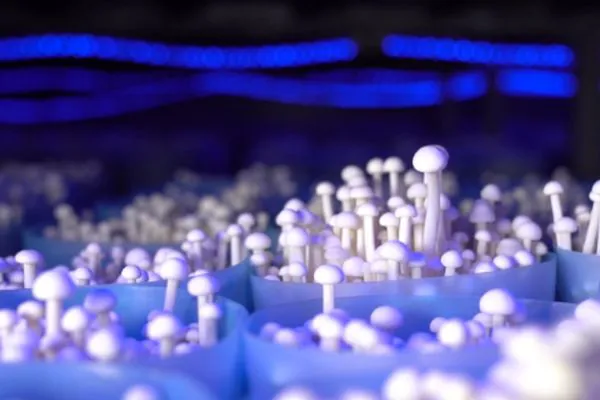

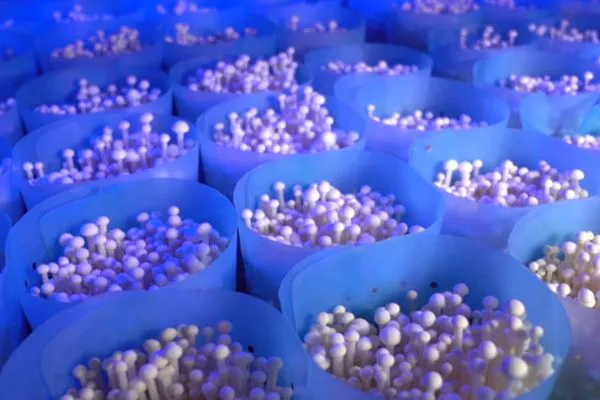

After spraying disinfectants and donning protective clothing, Jiang is taking reporters to visit the Flammulina velutipes breeding rooms. In these dark chambers with constant temperature and humidity levels, they were able to see a bunch of white velvet mushrooms protruding from cultivation bottles, shaped like little clusters of white clouds.

"Generally, edible fungus cultivation relies too much on subjective human experience. We have adopted the world's most advanced intelligent automatic bottle cultivation edible fungus production line, which has realized real-time monitoring and automatic remote control of the whole process of edible fungi production. The process standard can be said to have reached the leading position in the world," says Jiang Guobin.

The company's smart ecological mushroom cultivation base has completed the transformation of intelligent production from bag planting to bottle planting and is equipped with fully automatic temperature control, humidity control, ventilation, and lighting facilities.

All water and air used during the cultivation period can only be used after purification. The whole edible fungus production process is pollution-free, which not only improves the quality and output of edible fungi but also greatly shortens the growth cycle, breaks seasonal limitations, and achieves daily production.

Mushrooms are produced every day, realizing a steady supply of year-round organic fresh mushrooms to the market. Consumers can now eat high-quality edible mushrooms all year round.

"We have now broken through the technical bottleneck in the development and application of fully automated production of edible mushrooms. The yield per bottle has increased from 350 grams to the current 450 grams, directly reducing labor costs by 70% and increasing production efficiency by three times." Jiang Guobin says proudly.

In the fruiting workshop, the fully automatic assembly line runs continuously. Workers pack the screened velvet shank mushrooms into boxes and then transport them to the cold chain logistics compartment. All processes are orderly.

"Currently, the company can produce 150,000 bottles of velvet shank mushrooms per day, 70 tons of fresh mushrooms per day, and an annual output value of 185 million yuan," says Jiang Guobin.

With the continuous expansion and development of the mushroom cultivation base and market demand, the Kangrui Company has applied since 2010 to register the "Kangruiyuan" and "Yuxue" brand trademarks and was successfully selected into the first batch of the "Haopin Shandong" list in 2022, making it a regionally established brand.

"In the future, the company will continue to increase investment and build three more super smart edible fungus factories. After the projects are all put into production, the scale and production capacity of edible fungi will be at the forefront of the country and enter the capital market," continues Jiang Guobin.

A flower blooming alone is not spring, and the garden is full of spring with a myriad of purples and reds. Relying on the continuous development and growth of Shandong Kangrui Edible Mushroom Technology Co., Ltd., Dahuang Township, Qihe County, based on its own reality, devotes itself to cultivating the edible fungus industry.

Thanks to the County's model to drive small and medium-sized enterprises into large-scale research parks and growing facilities, this edible mushroom business has grown into a flagship model of Dahuang Township development.

Source: DeZhou News