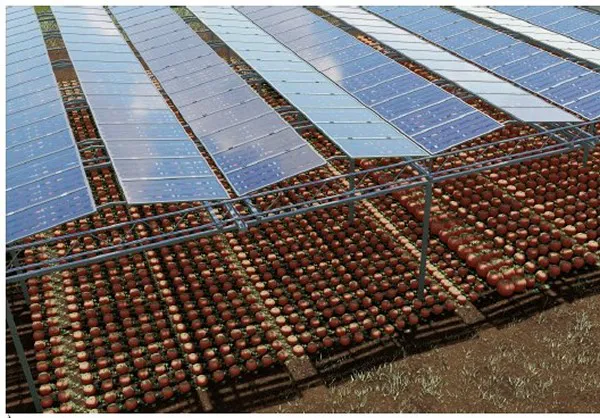

It is a well-known fact that agrivoltaic systems are a new solar energy production system that enables the cultivation of produce under structures up to 5 meters tall. Advanced agrivoltaics enables instead to meet two additional needs: protecting plants from the weather (hail, drought, heavy rain) and reducing water consumption thanks to controlled shading and the collection of rainwater.

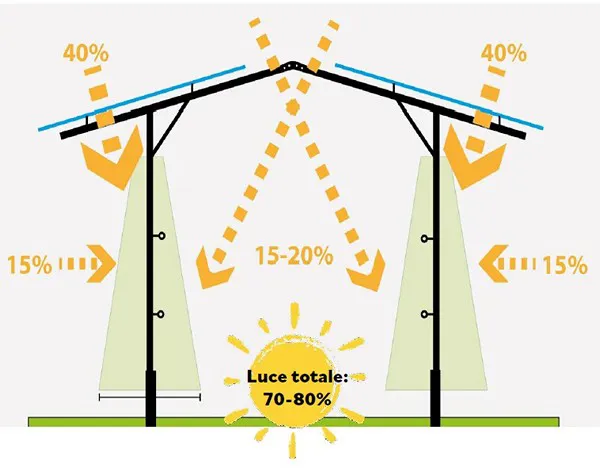

Many producers are however doubtful as regards the reduction of the light available to plants due to the excessive shade caused by traditional photovoltaic panels. This problem limits the type of crops that can be cultivated.

The quantity of light required varies noticeably depending on the type of plant: there are crops that manage to grow even with lower light quantities, e.g. potatoes and beetroots. Onions, cucumbers and zucchini are in the middle, then there are rapes, oat, carrots and cabbage. Many fruits like citrus fruits, berries, kiwis and pomegranates require slight shading, while wheat, corn and squash need more light.

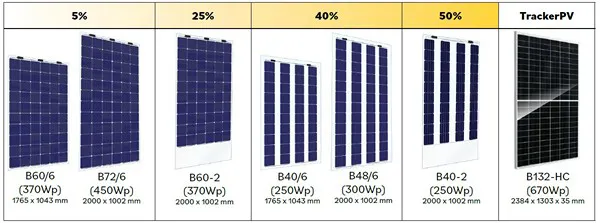

Oliva Service panel range

Oliva Service panel range

Oliva Service has been providing innovative solutions for 15 years. When it comes to agrivoltaic systems, it has been selecting innovative systems featuring very resistant laminated glass semi-transparent panels that let the light through with different shading levels depending on the type of crop. FreshPlaza has talked about them with sales manager Angelo Amato.

|

|

"We have developed different types of agrivoltaic systems that adapt to the various layouts:

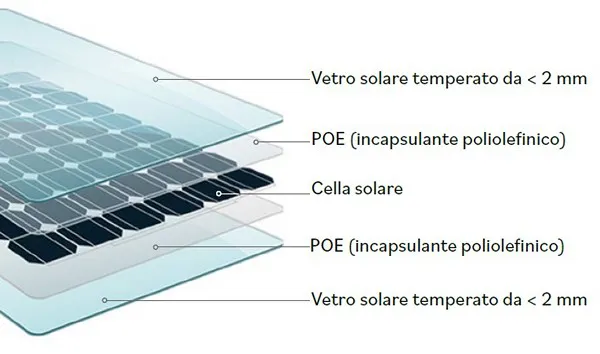

- Systems on steel structures up to 4-5 meters tall for the protected cultivation of fruit trees and vegetables, featuring double-glazed photovoltaic modules with different degrees of transparency. The power is up to 1,000 kwp per hectare, producing as much as 1,400-1,800 Mwh per hectare a year, equal to an estimated income of around €200m000. (Calculation based on the hypothesis of state funds equal to €0.10 per kw in Southern Italy).

|

|

- AgriPV systems equipped with semi-transparent solar-tracking for optimal electrical efficiency. They are ideal for crops that require large harvesting machines like vineyards and intensive and super-intensive olive groves. The distance between rows varies between 6 and 14 meters. Photovoltaic power up to 1,600 Mwh/hectare a year, equal to an estimated annual income of around €210,000;

|

|

- AgriPV systems on steel structures for large field crops with robust transparent double-glaze modules for protected cultivation, the protected stalling of animals and fish farms. System suitable for many crops including potatoes, beans, onions, Savoy cabbage, cabbage, berries, wheat, corn, artichokes, carrots, zucchini or squash with distances between rows of 7 to 10 m. Photovoltaic power up to 1,314 kwp/hectare and energy production up to1,900 Mwh/hectare a year, equal to an estimated annual income of around €220,000.

|

|

- AgriPV system with bifacial double-glazed vertical solar panels. Ideally installed facing east-west and suitable for the cultivation of vegetables and medicinal herbs, to fence pastures, for the energy improvement of green areas as well as wind barriers along roads, railways and highways. Large harvesting machinery can pass between them at distances between 6 and 12 meters. Energy power up to 900 kwp/ha and energy production up to 1,500 Mwh per hectare a year, equal to an estimated annual income of €150,000.

Bifacial vertical panels

Bifacial vertical panels

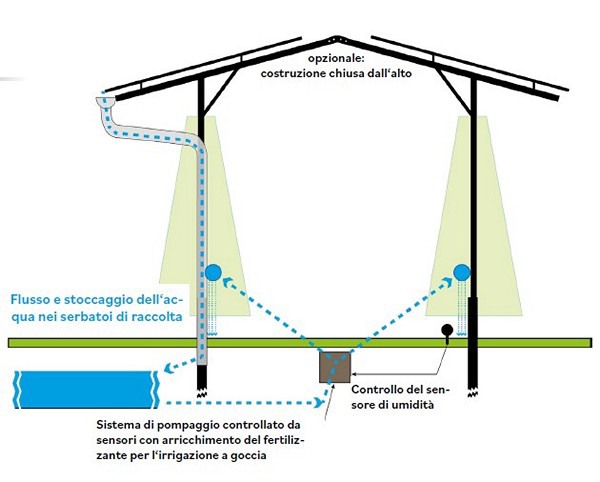

Many types of Oliva Service Agripv systems can collect and store rainwater thanks to an optional eaves system (see photo below). "The rainwater collected can be filtered, enriched with nutrients and used for drip irrigation via flexible hoses fixed to supports. If irrigation is controlled by humidity sensors in the soil, it is possible to save up to 95% of water."

|

|

Oliva Service can also supply all the types of sensors included in the next PNRR tender for advanced agrivoltaic systems: sensors for outside temperature, the temperature behind the panels, air humidity behind the panels, outside air humidity and air speed behind the panels and outside, in addition to sensors and drones for other agricultural and energy needs.

"Our research centers in Bolzano and Lecce are hard at work on the first open-air greenhouse pilot system that will introduce a new concept of "industry 5.0" by introducing robotics and green hydrogen."

For further information:

For further information:

Angelo Amato

Oliva Service

Via Perugia, 7 - 73100 Lecce

+39 0832/391652

+39 348/7849932

[email protected]

www.olivaservice.it