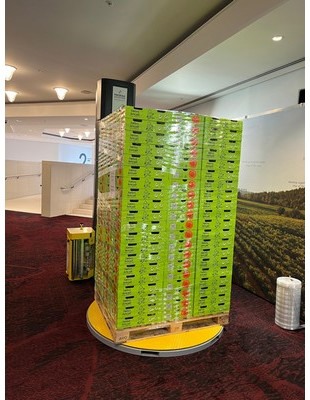

A leading Australian sustainable packaging solutions company, Propak Industries, has made an improvement to its Macro Wrap product to be able to tightly secure a pallet of fresh produce with as little as 82 grams of plastic.

"We do load stability tests, so that's our way of proving it," Account Manager Isaac Sandercock said. "I think our big focus is that we are not just saying it, but we will test it with the customer. We have done these tests ourselves to ensure that the load doesn't lose its strength. The way that we are able to reduce our grammage of plastic is that the new wrap is able to be stretched even further so that the strength of the load is improved at the same time. If you are using less plastic, it is firstly better for the environment, but you also get more pallets out of a roll. That means our customers are buying fewer rolls throughout the year, and that means less plastic they have to dispose of."

The product was on display at the recent World Avocado Congress in Auckland, New Zealand, and is set to have a more significant launch at Hort Connections in Adelaide.

"Our Macro Wrap has been around for many years, and it has been doing really well in the market," Mr. Sandercock said. "It helps people reduce their waste from original strapping and angle boards - as well as netted products that aren't recyclable. At times you could go from products using 800 grams and others as much as 1.5kg, but we were able to reduce it. With our older Macro Wrap, we were getting it down to around the 200-gram mark, but now we can get a 2.2-meter pallet done with 82 grams. We are still getting good breathability with that, and it is secured really well - and it is all done with our MAS350 Pallet Wrapper, which is our semi-auto model."

Propak has worked across the fruit and vegetable industries in Australia and New Zealand, with the avocado-related businesses one of the first to start using their products, largely in automation projects, including pallet wrappers, Macro Wrap, and ventilated wrap.

Propak has worked across the fruit and vegetable industries in Australia and New Zealand, with the avocado-related businesses one of the first to start using their products, largely in automation projects, including pallet wrappers, Macro Wrap, and ventilated wrap.

"We are still here today showing our support to an industry that has supported us really well," Mr. Sandercock said. "When we saw that the Avocado Congress was going to be in New Zealand, we thought that it would be really great to show our support back to the industry. Now that we are entering the New Zealand market with our products, it's a great time to show it has worked. We are doing tests with avocado pack houses here in NZ and show that the wrap has worked successfully in Australia. If anyone wants to see the product for themselves, come see us at Hort Connections. It's in our home city of Adelaide; we'll have the product, we'll have the load stability tool, the wrappers, and the scales."

Mr. Sandercock added that the major driver for the company is putting less plastic into the environment, which is becoming a bigger driver across the horticulture industry.

Mr. Sandercock added that the major driver for the company is putting less plastic into the environment, which is becoming a bigger driver across the horticulture industry.

"For myself, I love to see customers before their season starts and develop their programs further," he said. "So, the great thing with our pallet wrappers and wrap is they combine well for the fresh produce industry. So, I will go to their site, look at the settings and wrap that they are using, and we will figure out what will work best for them throughout the season, and that often includes what will reduce their plastic usage even more. I can also give them a breakdown of cost per pallet and how much they can reduce their plastic by - so then they go and tell that to their customers as well."

For more information on the company's team, products, and services, visit www.propakindustries.com.au.

For more information:

Isaac Sandercock

Propak Industries

Tel.: +61 8 8443 3522

[email protected]