De Terp Squashpackers has, in nearly 40 years, grown into one of the largest pumpkin companies in the Netherlands. "We organize the entire organic pumpkin chain, year-round, from seed to consumer packaging," begins Rinke Robbers. In April 2022, a huge fire significantly damaged the company's premises. But now, less than 18 months later, the new building is almost ready. Its capacity has been substantially expanded, including a renovated processing space.

"The convenience trend has increased tremendously in recent years, also with pumpkins. However, many varieties and kinds are offered with qualities that aren't suitable for that. That prompted us two years ago to start our own processing. Naturally, we choose the orange-red winter squash varieties, which are drier and have a nutty aroma. Our pumpkins are predominantly dry, typical, and thus very suitable for versatile use in the kitchen. These pumpkins' flavor and texture make all the difference," says Rinke.

He says taking on the processing work himself is a logical step. "The Netherlands cultivates about 4.5 million kilos of pumpkins annually, supplemented by around 2.5 million kilos of imports. That volume results in quite a few damaged/deformed products, such as broken stems. That does the quality no harm, but you can no longer sell these pumpkins loose to retailers. By processing the product, we can add value."

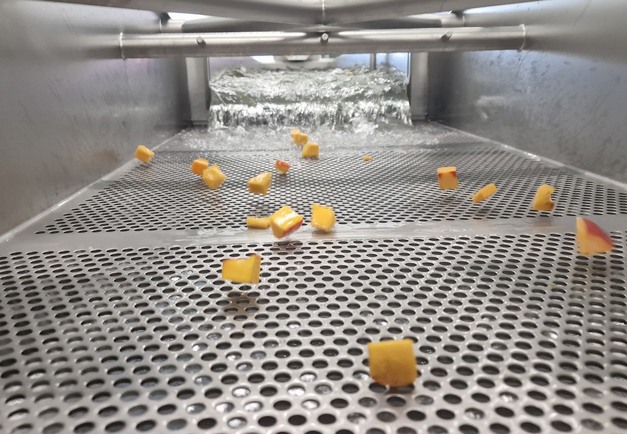

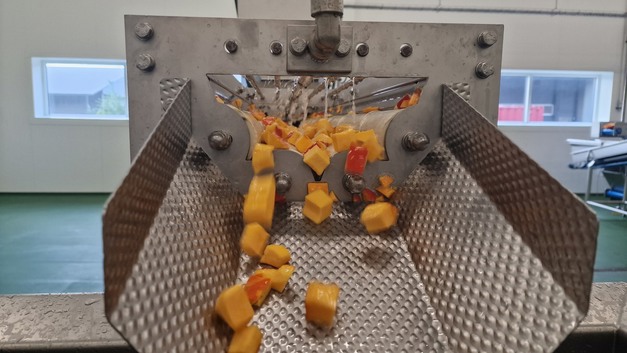

Thus, from October 1, the company will offer semi-processed red winter squash, both halved and in 10 to 20mm cubes. "We're taking a lot of work off the people's hands. They no longer have to buy and process raw material, and we can offer higher quality at competitive prices," Rinke explains.

"Processors struggle to process red pumpkins well; their seeds take up quite a lot of room. Fortunately, Hokkaido squash peel is edible and contains two unique carotenoid pigments, lutein and zeaxanthin. It would be a shame not to use these unique properties of the peel."

De Terp is getting another Dutch company, AGF-Direct, to market these semi-processed unpeeled Hokkaido squash halves and cubes. "Our plate is already pretty full with the cultivation and loose pumpkin sales, and the focus is 100% on getting production going well. So I'm super happy with the cooperation with Chris Groot. He's putting a lot of effort into bringing this new product to wider attention and connecting with new customers," Rinke says.

"I got to know Rinke because of Hokkaido squashes," says Chris. "A French retailer was looking for this type of pumpkin because of its taste. I firmly believe together, we have even more to offer. We expect to supply our broad client base of wholesalers, retailers, meal box suppliers, exporters, and processors with this semi-finished product. However, there's already interest from other quarters, like baby food manufacturers. The first buyers are already signing up. That's fantastic."

"Though De Terp has a strong foundation in winter squash, we're approaching this fresh-cut product as a start-up. Convenience is a completely different market, and I'm thrilled with the partnership we've begun based on trust. We're truly co-creating and working to move forward together. For example, next year, we'll have a joint stand at Fruit Logistica to promote this unique product," Chris explains. Rinke agrees, "For us, this is a totally new market, but it's an adventure we happily take on. Pioneering is something we've always liked doing."

De Terp's loose pumpkins were already IFS-certified, so that was not a big issue for the processing rooms. Pumpkin harvesting is now well underway, and, according to Rinke, expectations are high. "In some parts of the Netherlands, some plots have lower yields, but the crops look good in other areas, including ours. We should get good volumes and quality. We're looking forward to starting the processing, and from October 1, the first processed red pumpkins will go out the door," he concludes.

For more information:

For more information:

Rinke Robbers

De Terp Pompoenen

2A Lutterveld

4117 GV, Erichem, NL

Tel: +31 (0) 622 324 470

Email: [email protected]

Website: www.deterppompoenen.nl

Chris Groot

Chris Groot

AGF Direct

2 Groothandelsmarkt

1681 NN, Zwaagdijk, NL

Tel: +31 (0) 853 032 630

Email: [email protected]

Website: www.agfdirect.nl