In the 2023-2024 campaign, the acreage devoted to potatoes for fresh consumption in Spain has again been reduced in all producing regions. This, together with the impact of adverse weather phenomena of various kinds, has kept the supply low during much of the campaign, and prices have shown a generally upward trend. According to Juan Manuel Coello, commercial director of Patatas Meléndez, fresh potato purchases are falling to the detriment of industrial potatoes, so it will be necessary to make an effort in differentiation in order to reverse this trend.

"The data available confirm that the acreage devoted to potatoes has been on a downward trend in recent years, especially for those intended for fresh consumption, to the detriment of potatoes for processing, which are growing strongly," says the commercial director of Patatas Meléndez, the leading Spanish company when it comes to potato production and marketing. "Growers are dealing with increasingly higher quality requirements, greater limitations in the water supply and little generational replacement, and they also have access to more profitable alternative crops. Therefore, the production is increasingly in the hands of specialists and the sector has become more professional in recent years."

According to Juan Manuel Coello, fresh potato purchases have tended to fall in recent years, while the demand for processed potatoes (frozen, in prepared dishes, etc) has notably increased.

"As a sector, we have to make an effort to achieve the differentiation of fresh potatoes by betting on products with added value, looking for niches that will meet new needs. We have to facilitate consumption with formats such as microwave potatoes and highlight the organoleptic and culinary benefits of fresh potatoes compared to processed potatoes."

In the coming years, growth will be export-oriented

With a turnover of 110 million Euro in the 2022 campaign and an annual production of between 180,000 and 200,000 tons in the last few campaigns, the company from Valladolid plans to continue growing in terms of volume in the coming years, with a focus on exports and with products that will provide added value to the fresh market.

"Currently, we have our sights set on the export market, where we intend to expand our business, especially in Europe, in countries where we are already present, such as Belgium, the Netherlands, Germany, Denmark, Norway, Italy, France and Eastern European countries."

"This export expansion project will have two differentiated lines: on the one hand, we will try to take advantage of open commercial windows when the aforementioned countries do not have productions of their own, shipping sorted and selected products in big bags. These windows or gaps are certainly becoming wider and wider due to the changing global climate. While the gap for Spain used to be between May and June, now we can reach up to the end of August," he says.

"On the other hand, we will bet on another, more valuable line: ready-made products, be it flow-packed, in special formats for microwaves, or in other formats. In Spain we are able to produce potatoes of great culinary quality thanks to the characteristics of our climate, and since we have infrastructures in France and Portugal, we are very competitive in our international transactions, offering great quality and service in different segments with different varieties intended for specific culinary uses."

"In the last 5 years, potato cultivation has become more profitable for everyone"

In Castile-Leon, the main producing area in Spain, the 2023 potato harvest started at the end of June and continued until the end of October. Yields have been high in the first part of the season and more normal from the mid-season varieties onwards.

"The plantings were carried out nicely and the weather has been generally good. Prices have been high since the beginning of the 2023 season, with an upward trend that led to record highs in May, due to a low potato production in southern Spain caused by rain and frost. With the arrival of the Castilian-Leonese harvest, the supply increased and prices fell. There was also a high concentration of the supply, which was addressed with a good export output."

"When prices rise so much -and this year it has happened more notably- all parties involved in the value chain must make an effort to manage the rise in costs. Purchase prices and contracts have been updated to ensure profitability for the entire chain. If we look back 5 years, we can see how, as the sector has become more professional, with better planning and leaving the speculative model behind, potato growing has become more profitable for everyone," says Juan Manuel Coello.

Drought, the biggest challenge at the agronomic level

Drought has already become the biggest concern when it comes to production. The company has already felt the impact of this on the harvests in southern Spain, where water allocations have been lower and where the acreage has been reduced the most.

"At the agronomic level, drought is undoubtedly the biggest challenge for us. It is a cause for great concern. We are looking for earlier crops; for varieties that will be better adapted to this new reality, which will need less water. We are also looking for new production areas with more water," says the commercial director of Patatas Meléndez.

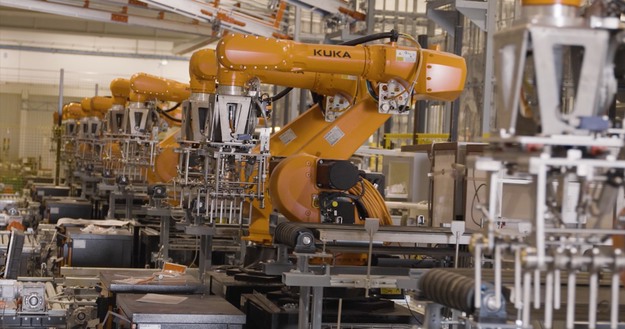

The most automated plant in Europe, which treats potatoes as if they were fruit.

The company, which has maintained its corporate model with Javier Meléndez as sole administrator, inaugurated its new 4.0 automated factory in March after having invested more than 36 million Euro in it. "We have the most automated plant in the sector at a European level. There are other factories with integrated automation, but they have not reached the point we are in, with automation implemented across the entire process, from start to finish," says the company's commercial director.

Some of the factory's most significant innovations include the optical sorters, which sort potatoes by size, shape and quality in a single process; AGV transport; anthropomorphic robots, which increase the packing production capacity; the implementation of a smart warehouse with capacity for about 1,000 boxes of 800 kilograms each, which represents an increase of more than 700% over the previous storage capacity; as well as greater energy efficiency and optimization of the water cycle.

"We are moving forward at cruising speed and already seeing the fruits of this investment. We now have amazing capacity to record data in real time, which can help optimize management in all areas. With this, we are improving our production efficiency, achieving greater sustainability and maximizing our quality standards, since we treat the potatoes as if they were fruit in all stages of their handling," said Juan Manuel Coello.

For more information:

For more information:

Patatas Meléndez

Tel.: +34 983 812 920

[email protected]

patatasmelendez.com