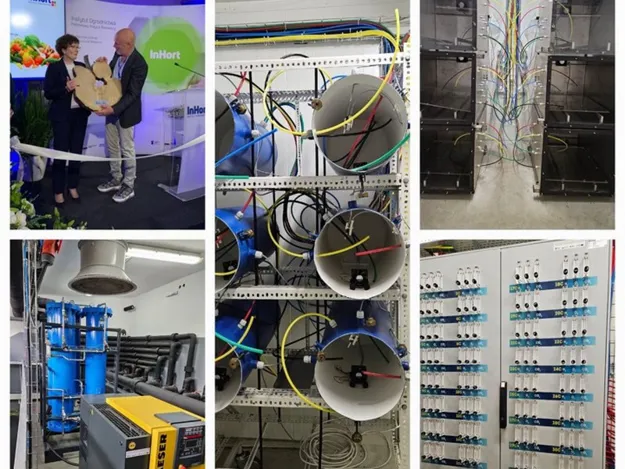

Van Amerongen CA Technology B.V. together with its partners has completed two remarkable Controlled Atmosphere (CA) laboratory projects. One at WUR in Randwijk, The Netherlands, and the second at InHort, Horticultural Research Institute in Skierniewice, Poland.

These projects were made possible through the financial support of the European Union and the commitment of all the involved stakeholders.

"Throughout the duration of both projects, we faced numerous challenges, ranging from the drafting of the bidding documents to the technical complexities of the projects themselves. Our dedicated engineering team designed bespoke solutions tailored to the unique needs of both our customers. With the support of our R&D team and on-site technical experts, we continually innovated to overcome any technical obstacles we encountered."

"It is worthwhile mentioning that these projects were carried out during the COVID-19 pandemic. However, our strong global network enabled us to source specific parts from various corners of the world, ensuring seamless project execution. Essentially, our team is open to communication 24/7. Once we accept the job, we guarantee high-quality delivery to turn your vision into reality.”

In both projects, Cooling and Controlled Atmosphere (CA) control are integrated into the My Fruit system. All CA units are equipped with the ACR (Dynamic CA) function, which calculates the most advantageous and lowest oxygen levels based on respiration of the products stored in the unit. In both projects the entire facility is monitored and controlled through the advanced My Fruit management system.

“At InHort we have successfully replaced a 25-year-old CA research facility. The transformation included the construction of 96 CA containers, 10 respiration boxes, and 2 shelf-life rooms, making it a state-of-the-art facility dedicated to post-harvest research in fresh fruit and vegetables. In a similar way we have at WUR Randwijk, we have constructed 4 small CA testing rooms, 3 cold rooms and 8 CA lab cabinets.”

People from all over the world are regularly visiting both projects to find inspiration for their own projects.

View the virtual tour of WUR Randwijk.

“At Van Amerongen, we are always pushing the boundaries of innovation and technology in the field of controlled atmosphere storage. We pride ourselves on our ability to undertake projects of all sizes, from small and delicate lab projects to massive 50,000-ton CA storage facilities,” states Niels Remmelink from Van Amerongen.

For more information:

For more information:

Niels Remmelink

Van Amerongen CA Technology

Email: NRemmelink@van-amerongen.com

www.van-amerongen.com/en