MSP Onions is a Dutch onion packer that reaches a global market with its exports of fresh onions. In 2018, MSP Onions embarked on a construction and development trajectory to create the factory of the future. This project has now been completed, and the company sets itself apart with a state-of-the-art onion factory in the Southwest of The Netherlands.

Lijn Moerdijk is General Director at MSP Onions. He explains the importance of improving its product quality and the sustainability of the business: "A natural product is different every year and requires flexibility and craftsmanship. Innovation and sustainability are key to our business operations. That is why we have invested in a smart factory, fully automated, and running entirely free of fossil fuels. Our automated sorting and packing lines ensure better quality products and competitive prices for our international clients".

Ten years ago, the cooperation between MSP Onions and Yongfeng Packaging started. Yongfeng Packaging is a producer of mesh bags, woven bags and nets for the fresh fruit, vegetable, and horticulture industries with production facilities in China and Vietnam.

Yili Dai is Sales Manager at Ningbo Yongfeng Packaging: "Our relationship started a decade year ago. Our lines of mesh bags are used on fully automated, highly efficient packing lines. It is very important for the companies that we work with that the bags run very smoothly on the packing lines. We worked together with MSP Onions to make sure the bags work the best on the machines the company employs".

He continues: "In this process, several problems have come up that jointly we were able to address. One of the problems that came up was that the bags were prone to having a little split at the bottom of the back after filling. We were able to solve this problem by applying an additional lamination at the bottom of each bag to strengthen it".

Netted bag with strengthened lamination applied at the bottom

Another problem was that the bags with labels, especially the metallic labels, started to stick together when pressed tight. The main reason for this problem was printing ink, which must have been slightly adhesive. After review at Yongfeng's factory, this problem was solved successfully by adding a unique solvent to the printing ink.

Yili adds to the story: "After careful review, our team realized that another way to solve the problem of the sticky logo is to not print the ink on the surface of the label, but print it on the inside instead. Soon we will start production with all ink printed on the inside of the labels".

"With new technological developments and new machinery, new problems arrive. We are here to work together with our partners to address these problems and find the best product solutions", continues Yili: "Future developments will focus on sustainability and environment friendliness. For our product lines, we are researching new materials that are stronger and lighter, so that fewer materials are needed. All our materials are recyclable. We have opened a new production facility in Vietnam of 130,000 square meters. We have installed over 30,000 square meters of solar panels".

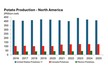

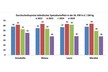

Lijn adds to the conversation: "This will be the future of entrepreneurship, to make sure that all future developments are sustainable. At MSP Onions, in our new building and production side, no fossil fuels are used. We have installed solar panels, purchased green energy, and we currently use technology that captures heat generated by the compressors in our facilities. In our market, we witness the stress coming from global warming and climate change. Onion market prices are high. Yield is higher than last year, but quality is lower. Extreme weather conditions, including high temperatures, rain, and drought are affecting onion production in different regions globally. Sustainable production and trade will be key to our futures".

For more information:

Yili Dai, Sales Manager

YEPP

Ningbo Yongfeng Packaging Co., Ltd.

www.yepp.cn

Email: [email protected]

Lijn Moerdijk, General Director

MSP Onions

www.msp-onions.com

[email protected]