The SiftAI Robotic Sorter from Smart Vision Works, a KPM Analytics brand, is the industry's first automated system for final potato inspection and sorting.

Fresh-pack potato processors often face challenges in staffing final inspection processes. Even with adequate staffing, defects can still reach customers, and acceptable potatoes are frequently discarded. The SiftAI Robotic Sorter offers a solution by automating the final inspection process, ensuring more accurate grading, reducing waste, and improving profitability.

The SiftAI system uses delta robots combined with an AI-based vision inspection system. Each system is programmed with AI models to assess potato size, and shape, and detect defects such as bruises, cracks, and discoloration. Installed over a roller table, SiftAI cameras capture images of all sides of the potato. Potatoes that fall outside the set grading criteria are automatically removed by robotic arms, capable of up to 80-100 picks per minute with two robot configurations.

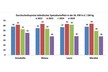

The system matches the speed and dexterity of human inspectors but with significantly higher accuracy, reducing customer returns and waste. Current industry standards allow up to 5% of defective potatoes to reach customers, but human inspectors often discard 10-20% of acceptable potatoes, lowering profitability. In beta tests, the SiftAI sorter significantly reduced both missed defects and unnecessary discards.

The financial benefits of automation are notable, with systems typically paying for themselves in under two years.

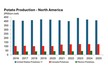

"Potato processors are under pressure due to oversupply and rising wages in North America," said Curtis Koelling, vice president of product development and innovation at Smart Vision Works. "Managers are keen to adopt technology that lowers production costs, and the SiftAI sorter offers a clear path to efficiency and cost savings."

For more information:

Andy Dambeck

Smart Vision Works

Tel: +1 774 399 0477

Email: [email protected]

www.prnewswire.com