Onedayone Group Zhangzhou has recently introduced a new filtering line for Chinese oranges, aiming to enhance product standardization and market competitiveness.

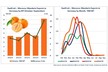

As the winter season sets in, Chinese oranges have reached their peak ripeness. Known for their thin rind, sweet flavor, and high moisture content, sweet oranges from the Hunan region are popular among consumers. Available from December through March, their success in the market is attributed to their taste and supply period.

This year, Onedayone has implemented high-precision categorization methods as part of its product standardization strategy. The newly installed filtering line in Zhangzhou grades oranges based on size, weight, skin quality, and other factors. This technology allows the company to meet quality standards and position its sweet oranges as a premium product.

"After being harvested, each fruit undergoes filtering and categorization," said Lan Bilong, General Manager of Onedayone Zhangzhou. "Our equipment ensures efficiency and consistency, guaranteeing high-quality fruit for consumers."

The new line improves production efficiency and extends the shelf life of the oranges by 15-20 days compared to previous methods. This aligns with Onedayone's strategy to meet market demands by reducing waste, enhancing product quality, and providing better value for consumers.

According to Lan, the stringent quality controls implemented during processing give Onedayone sweet oranges a competitive edge. The focus on standardized grading and specialized packaging has opened new opportunities in the market.

"Quality standardization is increasingly important in the fresh produce industry," Lan stated. "By developing grading standards tailored to market needs, we reduce waste, improve product quality, and enable premium pricing. This ensures a consistent experience for consumers and adds value for our distribution partners."

The new filtering line is part of a broader upgrade to Onedayone's product assurance systems. "Our pear business grew through better sorting and grading, and now sweet oranges are benefiting from similar advancements," Lan added. "Our goal is to deliver high-quality produce and improve the overall experience for our customers worldwide."

For more information:

For more information:

Maggie Peng

Onedayone Group

Tel: +86 187 17865462

Email: [email protected]

www.onedayonegroup.com