KRONEN delivered its first robotic solution for avocado processing in April. The tools and methods that the robot uses to pit and peel avocados were developed by KRONEN and have now been granted a patent.

They enable the sensitive fruit to be processed gently in an automated procedure and they play a key role in the unique Robot Avocado Line, which was showcased for the first time at this year's Fruit Logistica and Anuga FoodTec exhibitions. KRONEN developed the innovative solution in a research project in cooperation with the German Institute of Food Technology (DIL), and it is the only system of its kind on the market.

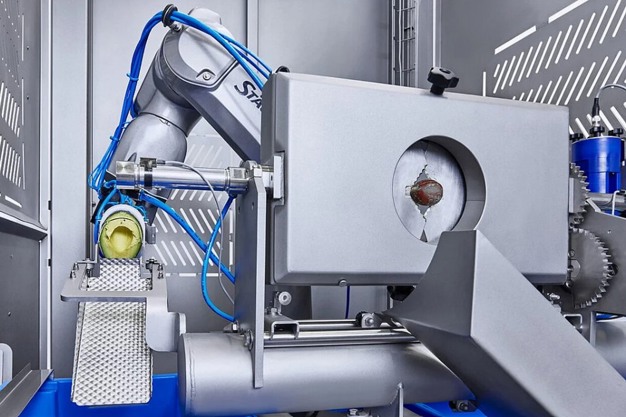

Ripe and ready-to-eat avocados are sensitive and pose difficult challenges when it comes to processing, which is why they have mostly been processed manually, even in industrial facilities, until now. Automated avocado processing using a robotic solution requires specially adapted tools that gently pit and peel the fruit while still enabling a high yield and an efficient process. KRONEN ticked these boxes by developing a method for pitting and peeling avocados with the help of specialized tools, and the company has now successfully received a patent for its unique idea.

Use of the method in the Robot Avocado Line

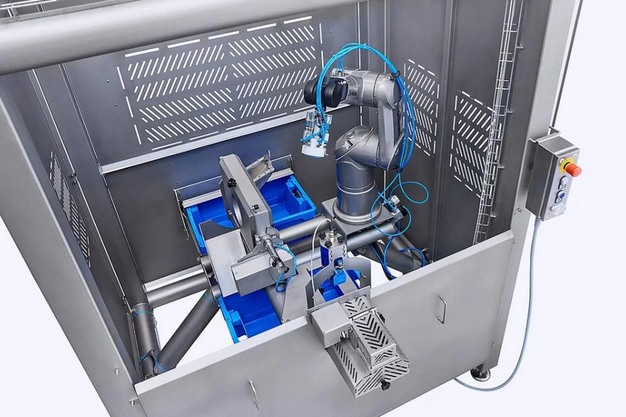

The tools and the method are incorporated into the Robot Avocado Line, which uses one to three robots to halve, pit and peel large amounts of avocados efficiently and hygienically, thus reliably ensuring a consistently high processing quality. Another reason for developing a machine-based solution is the fact that manual processing requires a constant turning movement, which puts a great deal of strain on employees' wrists.

A patent as a result of expertise, research and development

KRONEN worked together with the industry to develop the line from the first demand to the market-ready / industry-ready solution. "When developing the solution, we were able to make the most of our team's many years of experience when it comes to processing, especially cutting and peeling, sensitive food products. We also acquired comprehensive expertise on the properties and processing of avocados," explains Benjamin Keske, Project Manager at KRONEN.

"We then incorporated this expert knowledge into the robotic tools and processing steps, which we further developed by running tests and optimizing the solution based on the results. The combination of our developments with the robots from Stäubli offers companies that process large quantities of avocados a gentle processing solution with a high degree of automation.

Specially adapted tools for an automated processing method

Alongside its pitting and peeling unit, another component of the Avocado Robot Line is its grabber, which is specially adapted to handle the shape and texture of avocados and was developed by the DIL in its joint research project with KRONEN.

For more information:

For more information:

KRONEN

[email protected]

www.kronen.eu/video-avocado-robot