Has a tipping point been reached when it comes to robotisation in the agri-food sector? Experts believe it is imminent, according to the Asperge Innovation Day. It was held in Teboza's newly built shed and was dedicated to robotisation. Some 14 companies presented innovations in mechanisation and automation and growers were updated on the latest high-tech development by Jeroen Rondeel of Blue Engineering and Cindy van Rijswick from the Rabobank.

Click here for the photo report

In Teboza's shed, the asparagus sector gathers to learn about robotisation

High tech for everyone

High tech will soon be available to everyone, is the prediction of Jeroen Rondeel of Blue Engineering. Innovations driven by Moore's Law are going to drastically transform industries in the coming decades. "Moore's Law predicts that the computing power of computers will double every two years. This has driven technological progress for decades," he said. "And we expect this trend to continue until at least 2040, which means that by then computers will be a thousand times faster than they are today."

Jeroen Rondeel of Blue Engineering

He explained how this exponential growth affects the cost and accessibility of technologies. "Take 3D printers, for example. In just seven years, they have become 400 times cheaper. We see the same development in sensors and cameras. What is advanced technology today will soon become the norm," Rondeel predicted.

From medical innovation to industrial application

One of the most remarkable points in Rondeel's talk was the cross-fertilisation between different sectors. "The technologies we developed for the medical world, such as equipment for breast cancer screening, are now being applied in industrial sorting machines. This kind of innovation opens up new opportunities in agriculture and other sectors," Rondeel said. He referred to current applications in agriculture, where smart cameras and automated systems are already being used to determine leaf area index (LAI). "This technology helps farmers better predict growth and harvest. It is a perfect example of how high-tech solutions are bringing us closer to precision agriculture," he told.

Collaborative robots and flexible automation

During the presentation, Rondeel also addressed the rise of robots in the production and agriculture sectors. Collaborative robots, also known as cobots, can now work safely alongside humans without the need for safety gates. He cited examples of robots already being used to prepare salads and sort produce on harvesters. "The technology is so sophisticated that robots can now even do delicate work, such as picking up a banana, something that was impossible just a few years ago."

Robot can now pick up a banana without getting bruised

Hook up

Rondeel stressed the importance of companies catching on. "The speed of technological progress means that those who do not invest in knowledge and innovation soon fall behind. China has already realised this, investing heavily in robots and automation. If we want to remain competitive in the Netherlands, we have to act now."

Slow start, rapid acceleration

Cindy van Rijswick, sector analyst at the Rabobank, also says the time is ripe for far-reaching robotisation of the food sector. Whereas robots were often considered useless in the 1970s, the situation has now changed dramatically. Van Rijswick argued that we are on the eve of a revolution in the sector, with robots taking over more and more tasks and at lower and lower costs. "I think even my work will eventually become redundant," she said. "Tasks that are currently difficult to automate, such as hand-eye coordination, will eventually be performed by robots as well."

Cindy van Rijswick: "Investing in robotisation and AI is a no-brainer"

Why or why not to invest in robotisation

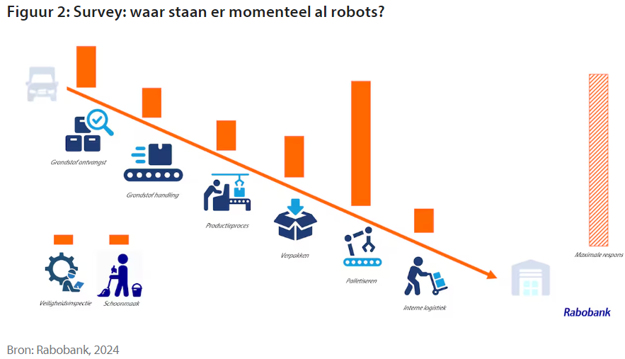

Rabobank recently conducted extensive research on robotisation in the food sector. Almost all companies indicate that the lack of qualified personnel is one of the main reasons to robotise. In addition, arguments such as working conditions, production costs, sustainability and flexibility also emerged. The penetration of robots in the food sector is still late.

Many companies do have a palletising robot (see figure above). This robot takes a lot of heavy work off employees' hands and is relatively easy to fit into existing processes. At other places in the production process, robots are few and far between. The new robots mainly appear at the edges of the production process (raw material handling, packaging) and internal logistics, according to the Rabobank survey.

Brake on developments

Many companies are still reluctant to invest. However, roboticisation is not a matter of taking the machine out, putting the robot in and moving on again. Besides the investment risk, robots require the necessary adjustments in the production process, staff training level and possibly even in the product range. "A company often has to be completely adapted to implement robotisation," Van Rijswick explained. "In addition, there is a lack of knowledge on how to use these technologies optimally." She also cited the seasonal nature of much work in the food sector as a challenge for robot adoption. "The development of robots in this sector is difficult to finance," she said. "Many investors consider it a risky category and prefer to invest in innovative food, such as meat substitutes."

Labour is driver

Van Rijswick pointed to an approaching labour market tightness after 2030. "The pool of potential workers will shrink, and the use of migrant workers is already under political pressure," she warned. "This will increase the demand for robotisation in the food sector." However, she stressed that robotisation is not just about cost savings. "It has to be a win-win situation," she argued. "Working with developers to create robots that fit a company's specific requirements will lead to more satisfied customers, less waste and sometimes more sustainable solutions."