An Australian agritech company is preparing to showcase its technology system at the World Agri-Tech Innovation Summit in London next week.

GoMicro has been selected by Ernst & Young to participate in the 'Accelerating Regenerative Farming with AI: Venture Pitch Showcase', and CEO Sivam Krish plans to launch a free ad-supported app, which will be available worldwide. He says democratising AI assessment helps growers meet supermarkets' and retailers' stringent freshness standards through AI assessment of quality and freshness.

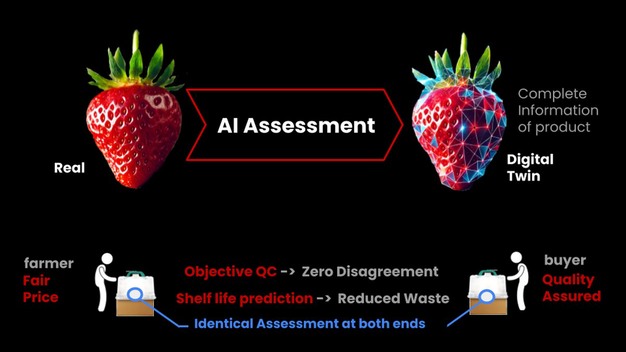

"It's a significant opportunity for us," Mr Krish said. "We think that we have something special as it can help solve quality-related problems within the agri-chain. We want to monetise this on the buyer's site. So, our plan is to connect the dots because quality control (QC) is subjective and those who buy are the ones who define quality. When it comes to fruit and vegetables you have QC people at different ends (of the supply chain) assessing quality differently. Even within the same company, QC people may not align. The food also spoils along the way, so it is not what you have at the end is not always what is initially sent. So how do you model this? There are IoT devices that pick up things like temperature and humidity, so we will combine that to work with create digital models we create. Allowing farmers and harvesters to convert what they have got into digitally tradeable goods will be a game changer; at the moment it is only size and weight and sometimes brix and harness measure that is used. But AI can help mine a lot more information. AI on the dispatch side will help prevent shipping stuff that gets rejected because everyone will have the same information."

He added that GoMicro's innovative technology not only accurately detects defects but also evaluates the freshness of fruit and vegetables, including strawberries and green leaf vegetables, ensuring that only the highest quality products reach supermarket shelves.

"Our other breakthrough is our ability to assess the freshness. A significant portion of fresh produce is wasted, because no one can tell how old the fruit or vegetable is," Mr Krish said. "With our technology, we have a phone-attached magnification device that can inspect the skin and just like humans where a man's skin is different from his son's, father's or even grandfather's. So, the technology can actually predict shelf life, and that has significant implications when it comes to reducing food waste and ensuring consumers get fresh produce. Right now, we are based on phone technology, so all our apps are running on phones. We are also working on the next generation that will have multi-spectrum lighting."

Dr Krish explained that while there are big machines in factories GoMicro is focused on doing it by phone and making it available at all points in the supply chain - from the farm to the packing station and the distribution centres -through to the retail shelves.

"Basically, AI is developing at a phenomenal speed and getting close to what you can assess by the eye," he said. "But I think we are at the point where we are exceeding human accuracy and one of the hardest things to assess is spoilage in fruits like strawberries. It's difficult because damages are very subtle and have skipped through commercial AI systems. This allows us to improve consumer satisfaction because, at the end of the day, markets want fresh and less damage. Also, most of the flaws occur after because any biological produce there are issues with maturity and spoilage; if you see something that is good then by the time it is on the shelf there's damage. This is why the ability to assess the subtle defects is important in horticulture before you can catch them early. All this just requires a mobile solution that also picks up the subtle defects, which we have cracked."

GoMicro has successfully completed beta tests with one of the largest supermarket chains in the United States for assessing strawberries and is also being used in the seafood and grains industry. The same technology is used for strawberries and green leafy vegetables and right now the company is doing spinach for Boratto Farms, in Australia, who are pleased with the result of using the technology.

"We are a solution for the entire food chain," Mr Krish said. "One big problem in agriculture is the different perspectives. The farmer knows the most about the produce and makes an assessment who sends it to the buyer and he makes a subjective assessment that is different from the farmer. This is a chaotic area that causes a lot of grief and disagreements - and in some cases, food waste. One way to fix this is for everyone to assess with the same equipment and to the same standards. If we do that, we solve a massive in the food industry. Our focus is to build a supply chain solution. So, a strawberry grower is using the equipment to see that workers are picking strawberries without defects, so you can then track this right to the shelf. You can cover the whole chain this way, and that's the way they are looking at it."

He says that, generally, AI apps have got a bad name, especially in Australia because of the cost involved in both developing and maintaining it and companies do not want to spend a lot of money on this. But GoMicro has found a cost-effective way of providing the service.

"One of the big problems that we have is that it requires 1,000 images, sometimes 10,000 to train an AI app. This is a huge cost for companies to develop an AI app. So, the key patented technology that we have developed allows us to train with a very small number of images; we talking in the hundreds instead of the 10,000s. The second thing that happens is that varieties change, and every season is different and things that come from one farm are different from another farm. So, this ability to quickly deploy and test at low cost is another huge advantage for us, because the amount of effort to build something that is good enough is huge because of the amount of information and for every flaw you need data."

For more information:

For more information:

Sivam Krish

GoMicro

+61 401 192 100

[email protected]

www.gomicro.co