Many growers and packing companies already know that overweight is one of the greatest challenges in blueberry packing. But let's be concrete. How much money you lose while working with an inaccurate weigh & fill machine? The quoted findings prove that some packing companies lose about 68k Euro per year due to overweight.

Overweight in blueberry packing – problem at scale

Overfilling happens when a machine or worker manually places too much fruit into a punnet. In this context, "too much" refers to even 1-2 grams over the intended punnet weight. Due to the nature of blueberries, it's difficult to avoid these slight excesses.

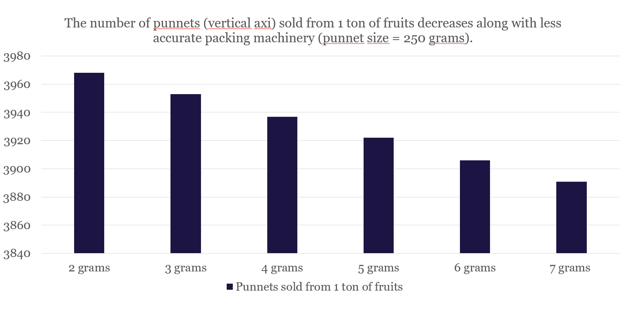

Discussing a few extra grams may seem trivial, but it becomes significant when you look at the bigger picture. Overfilling reduces the total number of punnets you can produce from a ton of fruit. Fewer punnets mean lower revenue, even though you've already paid for a ton of blueberries. Consequently, your costs remain constant, but your income decreases.

How much does inaccurate packing equipment cost you?

According to Milbor PMC's analysis, each single gram of overweight per punnet can cost you a lot of money. Obviously, all the outcomes depend on a few factors: the total volume of fruits per season you process, punnet size, fruit price, etc. For example, a company that uses a weigh & fill machine featuring 5 grams of overweight per punnet loses 68000 Euro per season, compared to an organisation that works on a machine with 2 grams inaccuracy.

At the bottom link, you can find more find an in-depth analysis and more numbers, comparing different punnet volumes (125, 250 and 500 grams) and machines showing diverse packing precision.

What is the remedy for overweight problem?

The packing equipment you use for blueberry processing plays a huge role in financial outcomes for your business. The link between accuracy of your weigh & fill and your incomes is straightforward. The best machines on the market can significantly reduce the volume of fruits giveaway for free and elevate your earnings. How to choose the best one?

"Nowadays, the manufactures offer us a broad range of packing equipment, but not all of them offer comparable performance, durability or weighing accuracy. At Milbor PMC, we work with weigh & fill machines by American manufacturer A&B Packing Equipment Inc. Thanks to advanced technology and unique construction, G3 Evolution secures only 2 grams of overweight which makes it the most accurate machine among linear weigh & fills. These 2 grams can be a real game-changer for those who use less accurate equipment so far," comments Maciej Chmielewski from Milbor PMC.

E-weights system to minimize overweight

2 grams of overweight sounds good, but you can reach much better results while implementing e-weigh system: "Our clients who selected average weight system, so called e-weights, get measurable results in terms of reducing overweight problem. Our experiences prove that 0,2-0,5 grams of overweight per batch is easily achievable for those who invested in the e-weights system. It is impressive, isn't? That's how it works when you pair technology with knowledge," adds Chmielewski.

Detect your losses

In the link below, you can find Milbor PMC's calculations regarding the overweight in the blueberry sector. These estimations will allow you to find out, how much money you can save by working with top accurate packing equipment.

For more information:

Maciej Chmielewski

Milbor PMC

Phone: +48 538 359 172

Email: [email protected]

www.milborpmc.com