Bluesky Hydroponics has unveiled its latest addition: a state-of-the-art cucumber sorting installation, specially designed for long English cucumbers. Located in Wheatley, near Leamington, Ontario, this facility is run by Jake Harms, who previously equipped his other greenhouse, Albuna Express, with similar technology. His positive experience led him to Aweta and Plantech Control Systems Inc. once again for a second automated sorting and packaging solution.

Bluesky Hydroponics recently expanded its operations with a new Universal Fabricating Venlo greenhouse addition of 17 acres (7 ha) for the cultivation of long English cucumbers. To meet the demand for quality production throughout the season, the existing boiler room has been expanded, and the new facility is equipped with technologies such as high-pressure fogging and a Meteor System GM-07 open gutter.

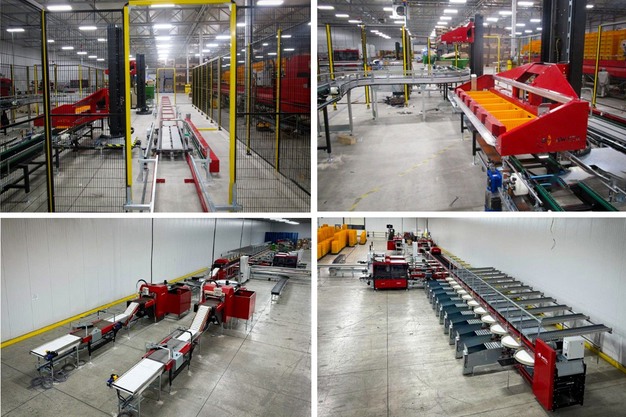

But the job isn't done before the cucumbers leave the greenhouse, and thus the logistics system also receives a lot of attention. The Aweta sorting system, developed in collaboration with Plantech Control Systems Inc, provides precise and efficient sorting and packaging, helping streamline operations and improve product consistency for high-quality cucumbers. "The installation is a robust addition, utilizing automation to handle increased demand while maintaining the standards Blue Sky Hydroponics is known for," says Jarrett Pennings and Cees de Groot with Plantech Control Systems Inc.

Given the high costs and limited availability of labor, automation is a hot topic in the Canadian greenhouse industry, and according to Cees, the advanced automation technology used at Blue Sky Hydroponics showcases the impact of innovative partnerships in greenhouse production. "Aweta and Plantech's expertise in sorting and packing automation continues to prove essential for high-efficiency produce facilities like Blue Sky, helping them address these challenges."

For more information:

Derek McLaughlin

Marketing Manager

AdeptAg

Cell: 440-420-0427

www.AdeptAg.com