After testing the Cydiance realtime monitoring devices in South Africa for 14 months under a wide variety of conditions, UTE now offers the Chinese company’s technology to the South African fruit industry because, according to Jan Lievens of UTE Miatech, it offers something that has hitherto often been neglected: attention to humidity levels during the entire transit period.

“We need a head shift with regards to humidity in the industry,” he says. “Producers often think that if the cold room has been calibrated to function at 90 to 95% humidity, that aspect is finalised but where does the moisture come from to maintain these levels? Often it comes from the fruit itself which, of course, defeats the purpose.”

“High quality requires high humidity because fruit and vegetables are basically packages of water but refrigeration removes moisture. Dry stems on grapes or shrivelled stonefruit are typical consequences of humidity problems. We are known as specialists in the applied postharvest technologies on the farm and are specialised in humidity, ethylene and airborne bacteria removal, hence our search for a product that could extend our top quality approach during the shipments from our clients.”

He notes that the high quality grapes from a South African grape grower using their full system, both in the packhouse and on their refrigerated trucks, has been eliciting favourable attention on the Shanghai wholesale market.

The Cydiance tracking device doesn’t use satellites, which has favourable cost implications. “UTE was approached in the past by various worldwide suppliers, but they could only give us temperature and location logging. Cydiance is the first to add humidity into these units,” Jan notes.

Filacell pre-cooling

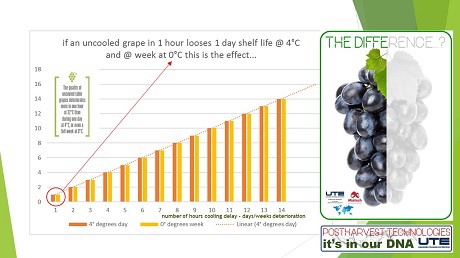

The company is also offering the Filacell pre-cooling system of Dutch refrigeration specialist Nijssen. Here, too, a high level of dry humidity is maintained, with a consequent extension of shelf life, coupled with very efficient energy use. According to Jan, with a power supply of 20 minutes the Filacell provides an hour of cooling.

The Filacell system, widely in use in the Dutch flower trade, has been employed in South Africa for many years. During trials in the US, grapes have been stored for 26 weeks in the Filacell system without a deterioration of quality, while in South Africa Jan has been involved with trials on lettuce which was still in top condition after six weeks.

Jan is looking at the rapid expansion of the blueberry industry in South Africa, and specifically the quick development of a post-harvest system for the new industry, with some concern. “There are many new packhouses but I don’t think they’re paying sufficient attention to humidity or the removal of ethylene and bacteria.”

“Many South African farmers will spend 95% of their time and financial resources to grow the best possible commodity and then, when it must be brought to market, sometimes throw the quality away within 24 hours through insufficient attention to postharvest technology,” he concludes.

UTE is also the approved South African dealer of Miatech (from Portland, USA) and a partner of Danish adsorption dehumidification technology provider Cotes. The company also advises fruit growers in Egypt and Australia on post-harvest technology.

For more information: Jan Lievens

Jan Lievens

UTE

Tel: +27 22 448 1002

Email: [email protected]

www.umhwebo.com