After the Covid-19 crisis, consumers are paying more attention to food safety, making higher demands on fruit and vegetable processing enterprises. Cleaning is an important step in possessing fresh-cut fruits and vegetables. Efficient and convenient cleaning equipment not only helps to improve a company's production efficiency but also safeguards the high quality and safety of fruits and vegetables that enter the market. Recently, Valencia, manager of Ningbo Lueon Industry Machinery Co., Ltd., a specialized manufacturer of fruit and vegetable cleaning machines, introduced the company’s latest offering of a second-generation in-basket cleaning machine.

First-generation in-basket cleaning machine

"At present, the most common cleaning method on the market is for fruits and vegetables to be poured into a cleaning machine and churned, and then transferred by a conveyor belt. Although it is effective in cleaning the produce, this method can easily cause damage to the delicate surface, increasing product loss during processing. Therefore, we proposed a solution of in-basket cleaning,” Valencia said. “The working principle of this machine is very simple. Workers put fruits and vegetables in baskets and then put the baskets in the washing tank. Bubblers are used to fully cleanse the residue on the surface while greatly reduce the damage caused by displacement and collision."

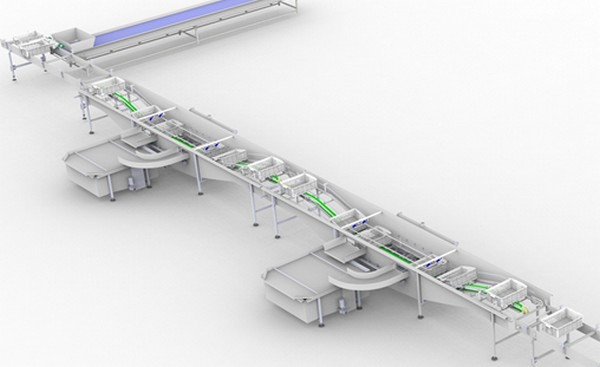

Second-generation in-basket cleaning machine

When talking about the advantages of this cleaning method, Valencia said, “First of all, for fragile fruits such as strawberries, cherries, and blueberries, in-basket cleaning can protect the surface of the fruit to the greatest extent. Loose vegetables such as leeks can stay near without being scattered during the in-basket cleaning process.

"Secondly, our second-generation cleaning machine has added many smart options. The staff can choose the most suitable cleaning mode from different modes according to the characteristics of vegetables and fruits. They can also adjust the parameters for cleaning and disinfection according to their needs. Thirdly, we have added a cleaning line where the baskets are conveyed continuously. The flanks adopt the form of chain mechanism so that no manual handling is required, which greatly increases cleaning efficiency and reduces labor cost and increases the production of the processing line up to 2 tons/hour."

Continuous cleaning

Ningbo Lueon Light Industry Machinery Co., Ltd. was established in 2003 and is one of the leading machinery manufacturers in the fresh-cut salad and vegetable industry in China.

For many years, Lueon has been committed to innovation and developing, designing, manufacturing, and providing specialized equipment and solutions for vegetables and fresh-cut salads, including peeling, slicing, washing, drying, and sealing.

"Our fruit and vegetable processing lines and equipment are serving more than 210 factories, and the fresh-cut vegetables produced are supplied to more than 8,000 fast-food chains in China every day, including KFC, McDonald's, Pizza Hut, Taco Bell, Dicos, Kung Fu, and Haidilao. We hope to expand our sales channels so that more overseas customers can get to know our cost-effective, convenient, and practical vegetable and fruit processing machines.”

More Information:

Contact: Valencia

Company: Ningbo Leuon Light Industry Machinery Co., Ltd.

Tel.: +86 (0) 574 65606120

Email: [email protected]

Website: https://www.lueon.com/