Data is becoming increasingly important in our industry and no more so than now, but how can we collect that data and what do we do with it when we have it?

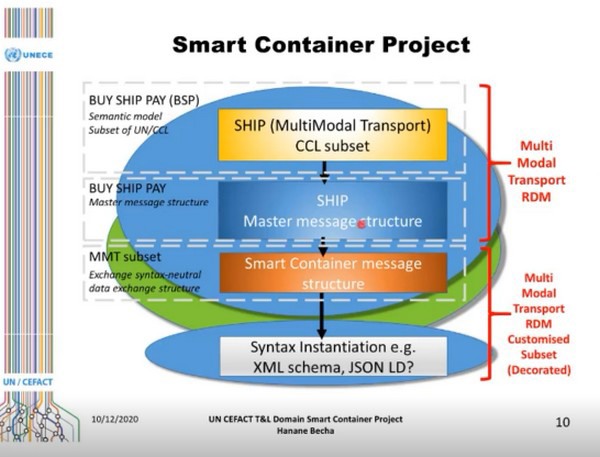

Hanane Becha, Project Lead IoT Program, DCSA Digital Container Shipping Association, said that standards for containers and reefers are no longer just nice to have but are now necessary to make sure we have a contactless supply chain. A mutli-modal international forwarding and transport COVID-19 project has been launched as well as a cross supply chain track and trace system.

She said that UN/CEFACT Smart containers are the solution if you want to know where your container is, when it arrived at the destination or what the condition of the goods are. The project was launched in 2017 when the governments of Brazil, France, Australia, USA and Italy started work on a white paper. The IoT device can communicate via embedded sensors, remote sensors and the reefer control unit.

Lissa D'Arcy, Solutions Integration Manager, Emerson Commercial & Residential Solution:

"We are in the midst of surviving a global pandemic the scale of which is unprecedented and the world is facing a lot of firsts, not least of which is the global distribution program needed to deliver a vaccine safely around the world. Where do we stand as an industry in support of that? She went on to outline the scale of this job and the challenged faced.

Don Miller, Chief Sales & Marketing Officer, Globetracker: "We are talking about the smart container but I’d like to talk about what happens after you sign that contract, when you get that deployment and how data plays a part in that."

Globetracker started around ten years ago and now dedicate their focus to cold chain and cold chain management. A shipping line says they want a smart container but what do they need to support that?

"Some of the lines are looking at the data they are getting and the value of it. Reefer is still highly competitive, but when there is data available it takes the question away from cost to data driven value. You are creating a bond with your customer through the data. Data has become indispensable and reefer owners can now give all kinds of data back to their customers."

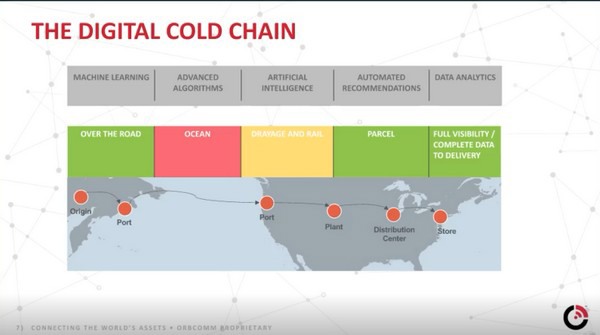

Al Tama, Vice President & General Manager of Container and Port Solutions, ORBCOMM: "We have long been talking about the digitalisation of the container space, but there still only a small percentage of the industry which is outfitted. We said a number of years ago ‘If the technology could be implemented what are the uses and what are the benefits of this technology?'

That IF is here but this sector of the cold chain is lagging behind. Containers are a large portion of the chain but it’s the one which has the least technology. The logistics and the cost have always been a barrier but recently questions have been as to how to adopt the right technology, this industry is not a one size fits all industry. There is a hunger out there for data from the cargo loaders and recipients of the goods to know where things are so they can prepare for eventualities.

"Looking at the cold chain, we need the data so we can apply the things in the top bar. It's not enough to just to know where the container is, with the data we have gathered over time we are able to apply our computing skills to use advanced algorithms and artificial intelligence to not only make maintenance and repair decisions but to help the end user."

Thierry Thevenot, Customers Operations Transformation Manager, Traxens, Identec Solutions: Thierry said that his company’s main object was to accelerate the digital transformation of the supply chain industry which was quite a challenge. Smart data can be used to create services and deliver immediate and tangible value to stakeholders.