The horticulture and agritech industries are at the start of the golden age of robotics and automation, according to a leading New Zealand-based company.

Rocos provides the support to connect robotics to what 'The Cloud' has to offer including AI, 3rd party API's and visualization, as well as helping to make the design, deployment and maintenance of multi-robot solutions easier and faster.

The company's CEO and Co-Founder David Inggs spoke at the recent MobileTECH Ag conference in Rotorua, and explained that year after year the capability of robots, especially in agritech, starting to become reliable and can work in the field autonomously for long periods of time.

"We are starting to see that robots are being implemented in some of the bigger universities and big kiwifruit growers," Mr Inggs said. "This is called 'Lab-in-the-Field', and these applications are immediately viable; you take a robot, put some sensors on it, send it out into the field, let it collect data and it can synchronise that data, like a mobile IoT-type of device. What we focus on is the thing called 'Physical Automation' - because it's not the robots that are what's most valuable at the end of the day. What is valuable is automation and doing physical automation. In agritech, we have been doing this for thousands of years, in changing the environment, and putting machines into the environments - but the big transformation now is the intelligence of these machines. The ability for these machines to carry out much more sophisticated tasks."

He added that the main challenges that technology providers are trying to solve include things like the shortage of labour, the global competition for markets and prices and sustainability practices. But the Rocos CEO says one of the main problems is identifying where is it that growers and farmers need to start. His advice is to gather an expert team that covers all aspects of what needs to be achieved, including an agriculture, mechatronic, software and economic perspective.

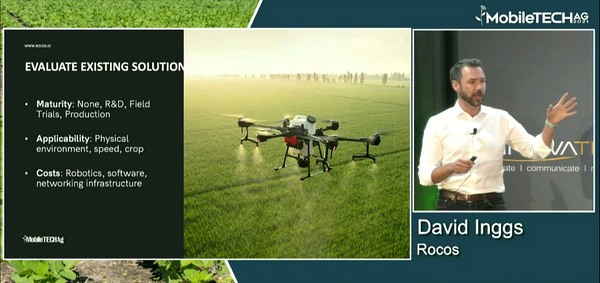

"The next thing is breaking down and identifying your individual processes, so there might be the Lab-in-the-Field processes or picking processes, harvesting or fertilizing," he said. "The other area we talk about is identifying each of those processes and evaluating existing solutions. The three categories that we talk about when analysing each of the processes are maturity, applicability and costs. So, if we took something like weeding as an example, the first question we'd ask is what is the maturity of existing robots for weeding? How many companies can you find that has a robot that you can put in the field and carry out the type of weeding that you're interested in? The maturity curve goes from none to R&D such as: is there academic papers that have lab trials of the robots? But taking something out of the lab and putting it straight into the field has its challenges, so that's the start of hope. Then there are field trials that are becoming more promising, but they are happening in limited environments. The last one is finding robots that are on production, and over the next few years more production robots will become available across your organisation."

The second factor, according to Mr Inggs is applicability, which refers to the physical environment. That means whether weather conditions such as snow or heat is going to be an issue, as well as the speed that the robot can do the job - such as picking or harvesting at the pace the industry requires and the type of crop. He says these factors play a big role in whether the robot will be practical to work in that location or company.

"Cost, the third factor, is also a big one, and we are finding that a lot of organisations who are investing in robotics and software, the pressure is not necessarily a return on investment in the short-term," Mr Inggs said. "So, they are not necessarily trying to solve a problem where you will get a reward next year. That's more of a factor when you are analysing more traditional technology that's been in production. But the pressure is that they know the costs of the robots, the software and implementation are going to come down significantly over the next few years. So, the costs have to take into effect that the reduction in costs, the intelligence of these machines will go up, the cost of implementation will go down and they will solve other problems. There is also the competitiveness threat, where if other industries solve it before you do, what is the competitive threat?"

He noted that growers and farmers often go down one of two main pathways when introducing robotics. The first being highly-specialised technology, where the focus is being given to one small specific area of operations and introduce them individually, rather than tackling all the processes at once, and the second is the use of generic multi-form robotics where the same machines can be used for fertilizing and mowing on different days. But as a company builds up its digital systems, Mr Inggs says it is important to bring all of the information together.

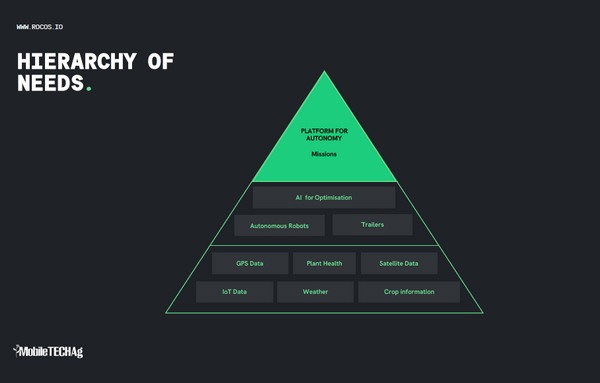

"So, some of the low-level data acquisition include IoT sensors in the field, such as weather stations, as well as plant health data, GPS data, data from the air," he said. "Ideally all this needs to be centralised, so it is available to the intelligent systems. In addition to this, you have autonomous robots, AI and machine learning optimisation. Ultimately what you are trying to get to is the concept of autonomy, where the systems are making decisions on what to do and carrying out the changes. So if that is a greenhouse that is monitoring the temperature or optimising the growth of a plant, or if it is robots going out in the field and deciding whether to mow today - ultimately you are trying to get to that centralised system to at least make those recommendations, if not actually run those operations, autonomously."

Rocos also admitted that companies who introduce IoT systems and robotics into their organisations need to factor in the ongoing maintenance and network connectivity issues, but more importantly that the technology chosen needs to be operated by the workforce, not just specialised academics.

For more information

David Inggs

Rocos

[email protected]

www.rocos.io