In August 2020 Tosca, a specialist in reusable packaging and supply chain solutions, acquired Contraload NV, a leader in plastic pallet pooling in the United Kingdom and European Union.

The acquisition of Contraload enabled Tosca to service supply chains end to end, from the first mile to the last mile. It also expands Tosca’s geographic reach and increases its product portfolio. Together the combined company offers customers more flexibility and better service.

Adrian Dale, Managing Director UK & Ireland, Tosca said that in this business a ‘one size fits all’ solution was not feasible so Tosca has it’s own R&D department which works with customers to create the perfect solution for them, this is Tosca’s big differentiator.

NeRa - heavy-duty, nestable rackable pallet

“Pallets have been the same since World War 2, so Tosca’s new NeRa nestable, rackable and stackable heavy-duty plastic pallet can deliver game-changing efficiencies throughout the automated distribution supply chain. We think it can revolutionise the flow of goods in many sectors,” said Adrian.

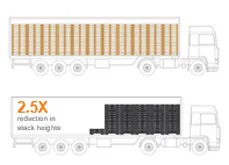

The NeRa pallet is heavy duty and can be used across many industries. Designed to outperform wood, the NeRa is the first plastic pallet engineered with PowerDeck™ strength and fitted with SureFoot™ legs for seamless automation. It is rated for static loads of up to 3000kg and is fully nestable – a unique combination that increases storage capacity while reducing space requirements by up to 2.5 times compared to wooden equivalents. Its robust yet lightweight design guarantees minimal deflection over time, making the NeRa Pallet ideal for highly automated sectors where it is critical to minimise product damage and avoid cross-contamination.

The NeRa pallet is heavy duty and can be used across many industries. Designed to outperform wood, the NeRa is the first plastic pallet engineered with PowerDeck™ strength and fitted with SureFoot™ legs for seamless automation. It is rated for static loads of up to 3000kg and is fully nestable – a unique combination that increases storage capacity while reducing space requirements by up to 2.5 times compared to wooden equivalents. Its robust yet lightweight design guarantees minimal deflection over time, making the NeRa Pallet ideal for highly automated sectors where it is critical to minimise product damage and avoid cross-contamination.

“It has been a long journey and in October of this year we manufactured the first 500 pallets. At the moment the pallets are available in Euro size and we will shortly move to manufacturing the sizes for the US market,” explains Jesse Sels, President EMEA, Tosca

“One of the biggest advantages of these pallets that they are nestable when empty. With standard pallets you fit 528 in a truck, with the NeRa pallet you fit 1221 in a truck, that adds up to 2.5 more capacity.

”In this time of truck driver and indeed truck shortages this is huge advantage, when you consider a country such as the UK which imports large volumes of fruit and vegetables from Europe but does not export the same volumes, you can considerably reduce the number of trucks on the return journeys. The impact on transport costs is huge, the cost of the NeRa pallets is very competitive on existing pooling pallets.”

Jesse points out that storage space at retailers is also limited, and these pallets would only use a fraction of the space of other pallets.

“The unique design is compatible for any conveyor system or stacker. The pallets are also designed to be very easy to clean. Sustainability is also very important these days and we see a life time of between 5-10 years on these pallets, this is obviously dependent on usage, the feet can be removed and replaced or repaired.

“We believe this is a real game changer for the fruit and vegetable industry.”

Asset IQ

In September this year Tosca added a comprehensive IoT service called Asset IQ to its broad portfolio of reusable assets. Tosca Asset IQ is supply chain IoT that delivers critical data and insights about supply chain performance. Partners will use it to find efficiencies and relieve bottlenecks, leading to better performance.

The Asset IQ service involves outfitting Tosca’s pooled reusable products with active IoT technology and reporting real-time data on a dashboard accessible to customers on their own computers and mobile devices. Tosca will work with customers to determine the best solution for them by combining the Asset IQ technology and products from Tosca’s broad portfolio of reusable pallets, bulk containers, displays, crates, and dollies that best suits the customer’s needs. Core capabilities include real-time asset location, the ability to pinpoint asset leaks, and monitoring of asset utilization, cycle times and overall pool efficiency.

The Asset IQ service involves outfitting Tosca’s pooled reusable products with active IoT technology and reporting real-time data on a dashboard accessible to customers on their own computers and mobile devices. Tosca will work with customers to determine the best solution for them by combining the Asset IQ technology and products from Tosca’s broad portfolio of reusable pallets, bulk containers, displays, crates, and dollies that best suits the customer’s needs. Core capabilities include real-time asset location, the ability to pinpoint asset leaks, and monitoring of asset utilization, cycle times and overall pool efficiency.

“This system can be used to tag not only our assets but that of our customers,” explains Jesse. “The platform will stop assets being ‘lost’ it can also tell us if assets are full or empty, this data can be used to optimise pick ups and make more accurate inventory counts, will also be able to generate more accurate forecasting.”

The system will also enable warehouse optimisation; product with the shortest expiry date can be moved out first and the operator will know exactly where to find it in the warehouse.

It will also build a history for the product for accurate traceability, which is essential for instances such as product recalls. For fruit being imported from other countries it is essential to track the supply chain, especially if the product arrives in less than optimal condition, the tags allow the customer to see when and where there have been breaches in the cold chain.

“We work with the customer to see what will fit best with their business,” explains Adrian “Sometime the technology is too expensive for small crates so we can use it on a small percentage of crates in a big order to find holes in the system and in pin point where things are going wrong. The tags can also be used to detect where promotional pallets are being displayed in stores it can even count the footfall past the pallet.”

Another example of how the tag is a gamechanger is in the home shopping E-crate. During the lockdowns there was huge demand for these crates as people turned to home delivery for their supermarkets shopping. Adrian said that when the tags were used on the crates, it completely changed driver behaviour and dramatically reduced crate loss.

Jesse said that they are tech agnostic, “We look at the platform which I believe is ahead of it’s time in terms of usability. Our customers can choose which data they use. The platform has only been live for a short time but have already received very good feedback from our customers.”

For more information: Maria Alonso

Maria Alonso

Publitek

T: +44 (0) 1582390980

maria.alonso@publitek.com

www.toscaltd.com