"The food boxes we produce are often made of food-grade PP and food-grade PET, but we also customize our packaging to meet the specific requirements of our clients for materials and colors." That is according to Ms. Li Lu of Zhejiang Qunlu Innovative Materials Co., Ltd.

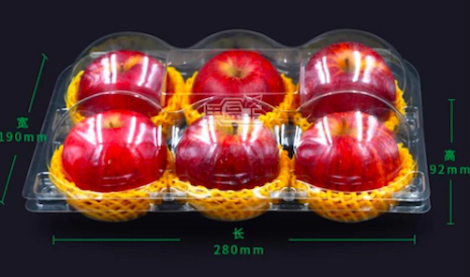

She recently introduced their food box products. "PP has antifreeze capabilities, which makes this material suitable for frozen food packaging. PET is more commonly used, for example, to package fruit. At the moment, we have an assortment of packaging boxes in more than one thousand sizes and shapes. Take fruit boxes as an example, there are huge differences in the plastic boxes used to package blueberries, pears, apples, or peaches. Even the same sort of fruit, like apples, can be packaged in boxes of between one and eight pieces of fruit."

Grape box

Apple box

"Regular fruit boxes can be divided based on product weight. The most common fruit boxes hold 0.25 kg, 0.5 kg, or 1 kg of fruit. These boxes can contain different kinds of fruit. However, some fruits have specific requirements, so they are packaged in customized fruit boxes. Either way, the quality of fruit boxes is very important. When fruit is transported via air freight, and the quality of the fruit boxes is not up to standard, then the packaging can split and damage the fruit."

Ms. Li continued to explain the differences between PP and PET. "PP can resist high temperatures and is, therefore, suitable for microwave products. Most microwave meals are packaged in PP boxes. PET will melt at temperatures of 30-40℃, so this material is not suitable for microwaves. The material is normally indicated on the bottom of the box."

Strawberry box

Packaging boxes

When asked about environmental protection and recyclable packaging, Ms. Li explained, "there are some regions where plastic is completely out of the question. But there are products where a replacement for plastic is difficult to find. Moreover, PET can be recycled as raw material for electrical wires and similar products."

Packing facilities

Ms. Li also analyzed the factors that play a role in the cost price. "The main factor in the cost price of food packaging is the material. PP is made from oil, so if the cost price of oil goes up, then the cost price of PP rises too. However, the impact is limited."

As for the demand for packaging products, Ms. Li added: "The demand for fruit boxes follows the seasonal nature of this market. Demand will grow during peak periods of fruit supply. Last year there was a huge demand for strawberry boxes. This year demand declined. In addition, the pandemic leads to occasional lockdowns, which impacts demand as well. Overall demand for food boxes is lower this year than in previous years. In fact, overall demand for packaging products has gone down in the last two years since the outbreak of Covid-19.

"Moreover, most demand comes from first- and second-tier cities, while third- and fourth-tier markets use significantly less packaging material. The main reason for this situation is the need for individually packaged fruit in big cities. Individually packaged fruit is usually premium fruit that has been through a careful selection process, and the main markets for such fruit are in major cities. Moreover, individually packaged fruit is not easily damaged by customers who cannot touch the fruit, and the packaging helps reduce the spread of Covid-19 as well."

Packing facility

Factory building

Zhejiang Qunlu Innovative Materials is a company that specializes in the manufacturing of food-grade packaging material. Their products include fruit boxes, fresh food boxes, cake boxes, and easy meal boxes. Their annual sales value is around 250 million yuan [37 million USD].

The company is engaged in long-term cooperation with strategic partners such as Hema Fresh, Ding Dong Maicai, Pinduoduo, Meituan, and other e-commerce platforms for fresh produce, as well as large-scale food companies like Hengdu Food and Sanquan Food. In addition to domestic sales, Qunlu Innovative Materials exports packaging products to Singapore, Japan, and the USA. Most of the export products are regular fruit boxes with a capacity of 0.5 kg, but the company exports customized packaging products as well.

For more information:

Ms. Li Lu

Zhejiang Qunlu Innovative Materials Co., Ltd.

Website: www.shqunlu.com

Tel.: +86 180 1775 2669

E-mail: 1358617831@qq.com