StePac, L.A. Ltd. analyzed supply chains it is closely involved with to assess how its packaging preserves the quality of fresh produce during handling, shipping and storing, and by doing so reduces waste and saves GHG emissions.

The company commissioned researchers at Wageningen Food & Biobased Research facility, Netherlands, to quantify the GHG emissions associated with the use of its Modified Atmosphere (MAP) products. The MAP products demonstrate abilities to reduce CO² emissions dramatically.

“StePac has demonstrated through this research that it helps lower GHG emissions by reducing waste in the fresh produce supply chain and often facilitating sea transport instead of air transport of produce to distant destinations. The reduction in GHG emissions far exceeds those generated in the full lifecycle of the packaging itself,” said Gary Ward, Ph.D., business development manager, StePac.

Jan Broeze, Ph.D., senior scientist of sustainable food chains at the Wageningen Food & Biobased Research, has developed a “field to fork” calculator to estimate greenhouse emissions associated with different aspects of fresh produce production and shipping. Calculations took into consideration the GHG emissions associated with the different plastic packaging solutions throughout the lifecycle. It also included data provided by StePac pertaining to waste reduction. Nine scenarios were examined, including melons from Honduras to the UK (Xtend® Bulk), blueberries from Peru to China (Xflow™), stone fruit from Spain to Brazil (Xtend bulk) and broccoli shipped domestically in Brazil (Xgo™ Retail).

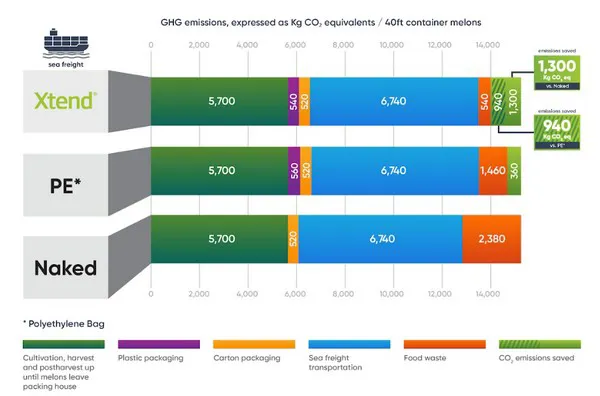

Results showed that GHG emissions related to plastics production, use and end-of-life are relatively small compared to other GHG emissions along the food supply chain. For example, in the shipping of melons from Honduras to the UK, the cultivation, harvest and postharvest handling represented 41 percent of the total GHG emissions of 701kg CO²/ton of melons.

In one example, shipping unwrapped Galia and cantaloupe melons from Honduras to the UK in 25+ days resulted in a high waste of nearly 18 percent. Due to its low water-vapor transmission rate (WVTR), polyethylene packaging with MAP properties is unsuitable and can result in waste levels of 12.5 percent or greater. The use of Xtend packaging with relatively high WVTR levels that eliminate excess moisture plays a key role in reducing the waste in sea freight to a minimum of less than 3.5 percent. In tangible terms, shipping four containers of melons in Xtend saves the equivalent annual CO² emissions produced by an average vehicle, estimated at 3020 Kg.

“Based on the research, StePac estimates that across all supply chains in which its packaging is used, it saved in excess of 100,000 tons CO² emissions in 2022,” said Ward.

“This research shows that StePac’s MAP solutions for produce can contribute to reducing emissions by facilitating sea freight and reducing waste in the supply chain,” said Broeze.

Meet StePac at Fruit Logistica 2023, Berlin, February 8-10, hall 5.2, booth #C-30

For more information:

For more information:

Hila Nagel

StePac

Tel: +972.4.612.3500

[email protected]

www.StePac.com