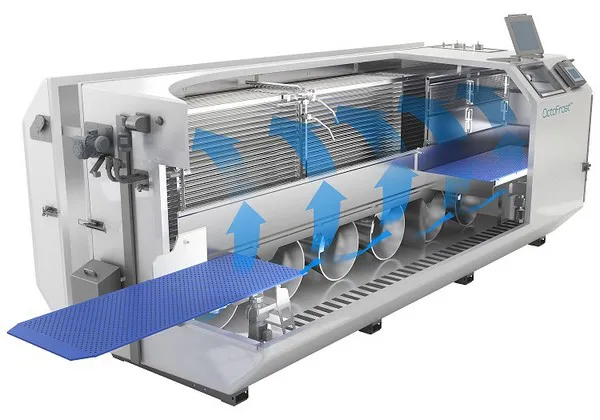

One of the difficulties that food processors encounter is choosing an Individual Quick Freezing or IQF freezer that is both effective and economical, says Sana Rehman, Marketing Manager at OctoFrost a Swedish manufacturer of IQF equipment: “This challenge has become even harder due to the recent increase in energy prices, which has affected the global economy and businesses. To cope with the rising energy costs, processors are now looking for energy efficient IQF technology to lower their equipment’s operating costs. Five key factors affect energy efficiency in an OctoFrost IQF Freezer: aerodynamics, the fans, the bedplate or conveyor belt, the coil design, and the housing along with the floor heating.”

Aerodynamics, the study of how air moves around objects, has a big influence on product dehydration, which in turn affects the quality of the frozen result, Rehman explains. “A complicated equation including the proper pressure, air velocity, temperature, freezer design, and fan design may be used to resolve this. The most recent advancement in IQF technology, fluidization, enables the IQF product to act like a fluid and be gently handled to keep its shape. The appropriate mix aids in fluidization. Shorter freezing times can also result from efficient aerodynamics, which minimizes dehydration and increases freezer capacity.”

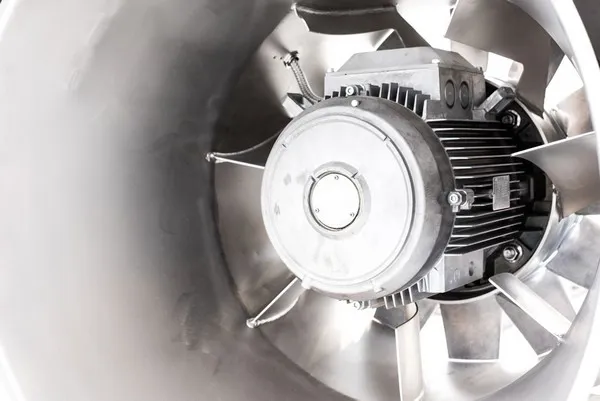

A lot of IQF tunnel freezers frequently run their fans at maximum capacity, which can result in significant energy consumption and product damage from overblowing. “The OctoFrost IQF freezer, in contrast, employs vane axial fans with adjustable speed. This customisation enables processors to adapt each fan's speed in accordance with the specific features of the product, resulting in a fan speed need that is normally no more than 75% to 85%. Additionally, the fan's design enables improved airflow control, which can save up to 30% on energy,” Rehman states.

“The majority of IQF freezers have conveyor belts, which increase product-belt friction and requires more energy to maintain the cooling capacity. Contrarily, our bedplates are made with a certain thickness and hole arrangement to accomplish the desired fluidization, resulting in less energy use and no product adhering to the bedplate,” says Rehman. “The amount of heat evacuated depends on the size of the coil within the IQF freezer. Because of the bigger coil in the OctoFrost freezer, the fans may run at lower speeds while still maintaining fluidization and the required cooling effect. Additionally, compared to other freezers, the coil has a bigger front area, prolonging the time between defrosts.”

Finally, to keep the floor from freezing and harming the equipment as a result, traditional IQF freezers need floor heating, but Rehman explains that the OctoFrost line doesn’t need the heating: “The OctoFrost IQF tunnel freezer, on the other hand, has a body that stands on its own supporting feet, guaranteeing great insulation and eliminating the need for floor heating. In conclusion, if food producers want to lower their equipment's energy consumption, they must purchase an energy efficient IQF freezer.”

For more information

OctoFrost Group

Email: [email protected]

www.octofrost.com