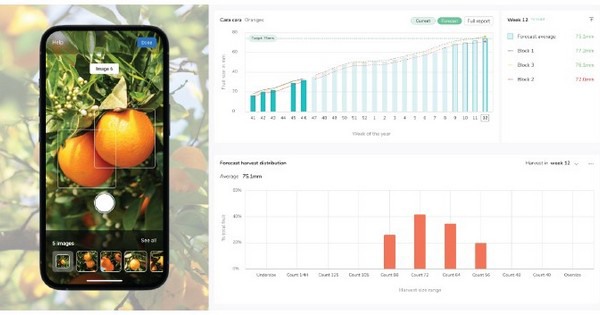

Aerobotics' app allows growers to capture yield information on the ground, by taking pictures of fruit on the tree. The AI software automatically identifies and sizes the fruit, saving time and allowing for much larger sample sizes to build weekly size distribution graphs. More importantly, Aerobotics helps growers understand where in the orchard the fruit size is developing to better help growers mitigate orchard variability early season.

Aerobotics’ Europe General Manager Bernardo Costa, says the company has really focused on incorporating feedback from growers to build something that growers can adopt and immediately see the benefits. “Our fruit sizing solution does not require any specialised or expensive equipment, only an iPhone. Although we initially launched this technology for citrus, it is now available for sizing apples, stone fruit, cherries, pomegranate, and grapes,” says Costa.

So how does this technology work? Growers can immediately start sizing once their farms are set up on the platform. Aerobotics’ sizing algorithms can accurately size fruit from 10mm. Users take the pictures in the app, which requires no connectivity in the field, and upload the images at the office over WiFi. 24 hours later, the data is available online in block, farm, and cultivar view dashboards.

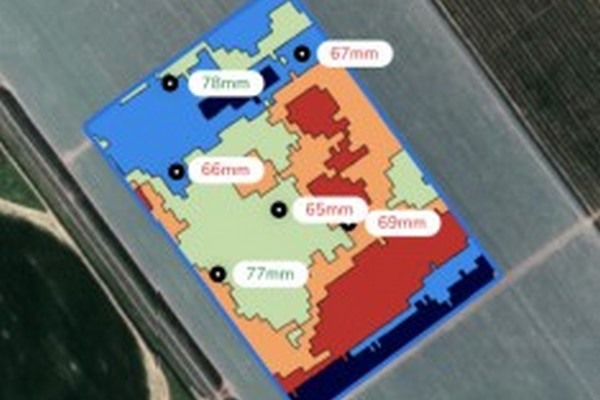

The sizing can be used with Aerobotics’ drone survey solution to identify representative sample locations. An aerial survey of the entire farm helps growers understand the variation in the blocks of key tree performance metrics such as health, canopy area, and transpiration. Costa says, “We have seen strong correlations between the different performance zones and average fruit size. Fruit sizes can vary significantly depending on how well the trees are performing in the different parts of the block so gathering data from a representative sample is important.”

Costa added that by tracking and analysing the fruit size regularly throughout the season, Aerobotics’ clients know whether they will hit the desired range or if the harvest will be bigger or smaller. This helps to pinpoint which blocks are underperforming and can focus efforts on making improvements. "They could maybe do another round of fertiliser or anything else agronomically that could manipulate the crop to achieve the desired size so they get the highest return on investment, which is the key goal for anyone in agriculture," Costa says. The data also helps growers allocate which blocks can go to which markets based on size and plan the harvest ahead of time. Knowing where you will end up with your peak counts at harvest time is also beneficial to fruit marketing businesses to fix their export programs early on in the season.

Since Aerobotics launched this new technology, over 2 million pieces of fruit have been sized. Originally founded in Cape Town, South Africa, the company is operating in 18 countries, working with some of the largest fruit businesses in the world.

For more information:

Aerobotics

South Africa: +27 21 035 1060

United States: +1 772 584 9762

www.aerobotics.com