"Turkey is becoming increasingly competitive in the production of fruit and vegetables, and strawberries stand out," says Angelo Sicignano, sales manager of PND, an Italian company specialising in the manufacturing and marketing of fruit processing machinery. A year after joining PND, the manager speaks of a new major success for the company, "which sees the largest semi-automatic strawberry processing line in the country installed in Turkey."

Angelo Sicignano.

Angelo Sicignano.

"The installation consists of eight DF24 de-stemmers," explains Sicignano, "designed and engineered to minimise manual labour, production waste and mechanical damage to the product.

The sales manager for Turkey, Spain, Portugal and South America added: "This is an important sale that opens the door to an emerging market with a top reference for Turkish fruit growing. Turkey has huge potential to become a major player in the global strawberry market and we expect this plant to lead the way for radical and widespread process industrialisation in the country."

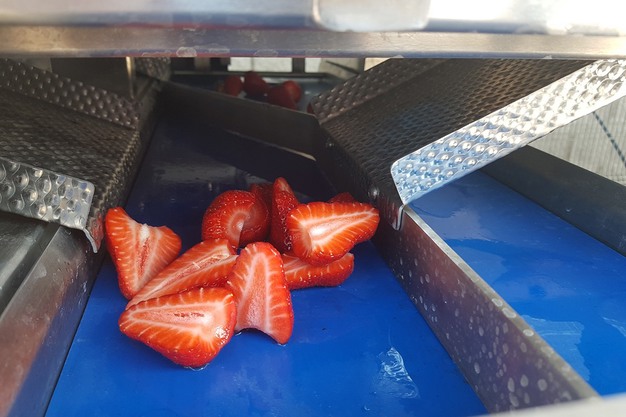

Strawberry processing plant.

Strawberry processing plant.

"The system is able to calibrate and process in-line strawberries of different sizes and shapes, with diameters ranging from 18 to 50 mm," explains the expert. "The process removes the green top part of the strawberry, and on request, the machines can cut the strawberry into halves or quarters, guaranteeing an excellent yield and preserving the natural shape of the fruit. Processing takes place in three stages: product orientation, removal of stalks, and fruit ejection (which can occur at the same time as the cutting stage, if the customer so wishes).

"The DF24 model is a semi-automatic machine built entirely in stainless steel and plastic and certified for use with food products," explains Sicignano. "The machine was created 10 years ago and has been optimised over time to become very versatile and powerful, and has received a good response from users, with more than 130 units sold worldwide. The decision to invest in PND machines stems from the fact that the Df24 model has numerous advantages over alternative models on the market: the machine preserves the natural texture of the product, reducing mechanical stress to a minimum; it minimises production waste and preserves the natural shape of the fruit thanks to the conical cut of the stalk."

"We are sure that our strawberry processing equipment will increasingly be the best choice for all operators in the strawberry processing world, thanks to PND's continuous research and development in this area," he concludes. Customer care is a key priority, from the design phase, through the purchase and commissioning of the machine, to technical and after-sales support in any part of the world."

For more information:

Angelo Sicignano

PND - Fruit Processing Machinery

Via Brancaccio, 11

84018 Scafati (SA) - Italy

Tel.: +39 0818509368

Email: info@pndsrl.it

www.pndsrl.it