Back in 2005, WECO started a dedicated division for the sorting of blueberries. Since then, equipment and capabilities have significantly advanced and the company proudly showed their very latest addition, the 360Tek Sortivator, launched in March of this year. It is a compact sorter that is positioned at the end of WECO'S Sortivator blueberry line. "This sorter is a differentiator because of its small footprint and high throughput as well as its ability to spin the berry 360 degrees and take up to 16 photos," says Eric Horner, Vice President with WECO.

Small footprint

The 360Tek Sortivator for blueberries comes in two sizes, 20 and 40 inches wide. It detects small defects as the berries fall into the pockets of hour-glass shaped rollers. From there, they make their way over to a camera system that takes up to 16 high-definition pictures with advanced machine learning technology (AI). In addition to removing fruit with defects, the 360Tek can easily be configured to also identify jumbo fruit from regular fruit in the same run. Despite its small footprint, 360Tek has a throughput of up to 8,000 lbs. of blueberries per hour depending on size. "This is more than double what other category sorters in the industry can do and in a much smaller footprint," commented Horner.

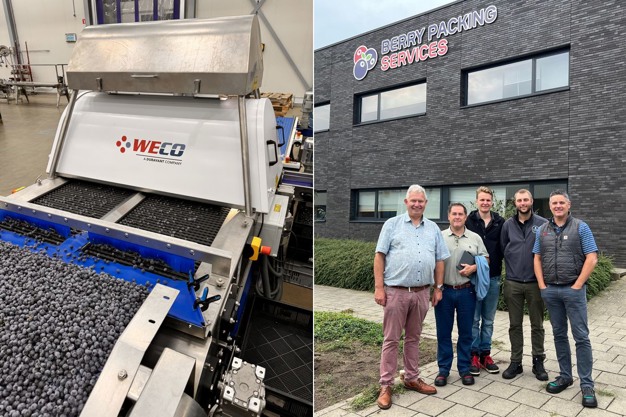

The first 40-inch wide 360Tek can be seen in action at Berry Packing Services in the Netherlands and 20-inch sorters have been installed in the U.S., in Florida and Oregon. Outside North America, a total of eight 20-inch sorters have so far been installed in six different countries in Europe, including Poland, Germany, France, Italy, Spain, and Serbia. "Seeing it in action, the 360Tek is the missing link to a traditional blueberry sorting line," said Horner. "I believe it is game changing technology for our customers and the blueberry industry." The latest technology in blueberry sorting was co-developed with Multiscan Technologies, a sister company of WECO. Both companies are owned by the Duravant family of companies.

Left: 360Tek Sortivator. Right: Harm Valckx (Berry Packing Services) and Carlos de Miguel, Elias Stenzel, Brett Rietveld and Eric Horner from WECO/Multiscan.

Other modules of blueberry line

The modular technology allows for different types of sorters to be added to a line. The 360Tek comes at the very end of the line and is preceded by a blower (elevator) that removes small debris, dried flowers, as well as undersized berries. Following the blower is the BerryTek Sortivator, also a common part of a blueberry sorting line. This two-view color and soft sorter removes red and green berries as well as overripe soft berries. The bank of cameras on the top and bottom of the machine have the ability to scan two sides of each piece of fruit.

The Impulse Soft Sorter is another common element of a blueberry line. This sorter also measures the softness or firmness of the fruit and removes soft, defective berries. In this case, the berry makes contact with a sensor. "We offer two types of sorters to identify softness as not all soft berries are created equal," commented Horner. The BerryTek and Impulse are used in 95 percent of blueberry line configurations that have been installed.

Click below to see a video of the entire line.

Equipment rental

WECO was established 40 years ago and initially only focused on the processing tomato industry with a tomato sorter on the harvester. "From the start, we've been offering our customers the option to rent our equipment," shared Horner. Rental contracts come with service as well as upgrades to the equipment. Currently, the company rents out equipment to customers in the U.S., Canada, Mexico, Chile, Peru as well as different countries in Europe. Service facilities across the globe maintain the rental fleet. "Service is our secret sauce and it's how we differentiate. Harvest is short and uptime of equipment is critical," he said.

Asia Fruit Logistica

WECO's blueberry sorting lines operate in North America, South America, Europe, Australia, and South Africa. The company is looking at expanding into China and will be attending Asia Fruit Logistica in Hong Kong next month.

For more information:

For more information:

Eric Horner

WECO

North America, South America, China

Tel: (+1) 425-802-3313

[email protected]

www.wecotek.com

Carlos de Miguel

Carlos de Miguel

Multiscan

Europe, Middle East, Africa

Tel: (+34) 96 533 18 31

[email protected]

www.multiscan.eu