These days, the high-tech industry often directly drives innovations, yet it seems there is still room for experienced agricultural product companies, like Swiss company Visar Sorting. DT Dijkstra, a Dutch company, supplies processing lines. It is also a dealer for Visar Sorting - which provides optical carrot and potato graders - in the Netherlands and Belgium.

"Visar Sorting's grading solutions use ingenious software," says Harco Christiaens, International Sales and Aftersales Manager at DT Dijkstra. "The developers and software specialists view the products from a cultivation perspective. That makes a difference. Those people truly understand what potatoes and carrots are and that those products are subject to diverse influences."

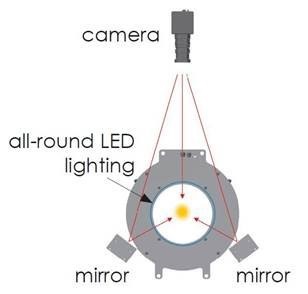

Visar Sorting is known for its innovative graders. These use a short moment of flight between two belts and LED lighting for constant background reference, resulting in high-resolution images and a detailed 360° assessment of each product. The technology cannot yet see through the potato and carrot peels, mainly focusing on external quality characteristics. Internal quality measurements should, however, be possible in five years. The company has already developed machines for the seed potato sector. These meet the standards of the Dutch General Inspection Service, which oversees propagating material's quality and health.

Visar Sorting's machines have proved their worth by minimizing quality losses in seed potatoes and identifying marketable products that would otherwise be lost. The machines can handle, on average, five tons per hour for carrots, 14 tons/hr for washed potatoes, and six tons per hour for seed potatoes. That offers a significant advantage over traditional mechanical grading processes, which often require extensive manual labor. Optical sorting solutions can significantly reduce labor needs, saving costs and increasing the sorting's consistency and accuracy.

DT Dijkstra already has comprehensive mechanical solutions for the carrot market, like drum washers and logistics systems. And, now, it is adding Visar Sorting's optical sorting solutions, allowing for grading carrots to multiple quality standards and increased sorting flexibility and efficiency. The machines can have up to 16 different outputs, enabling a high degree of sizing and quality control.

DT Dijkstra and Visar Sorting will be at Interpom in late November, showcasing their latest seed potato optical sorter. That marks an important step in their partnership and the further expansion of their technology in the Dutch and Belgian markets. Nine Visar machines have already been installed in the Netherlands. These are performing well and contribute to the efficient, qualitative grading of agricultural products.

![]() DT Dijkstra

DT Dijkstra

Landbouwkade 6

8304 AE Emmeloord

+31 (0)527 30 77 00

[email protected]

www.dtdijkstra.nl