Agritech company Aerobotics aims to close the gap between innovation that no-one has yet thought of, and the actual pain points on a farm, says client success manager for EU and Latam and agritech enthusiast Ken Treloar.

Agritech company Aerobotics aims to close the gap between innovation that no-one has yet thought of, and the actual pain points on a farm, says client success manager for EU and Latam and agritech enthusiast Ken Treloar.

Drone flights gathering orchard data made the company's name first in Southern Africa, then in the United States and beyond. Two years ago the company, founded ten years ago, introduced yield estimation technology, and their newest foray into AI agritech is fruit sizing throughout the growth period called TrueFruit.

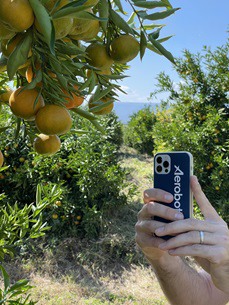

At Fruit Logistica in Berlin, Aerobotics handed out iPhones loaded with the TrueFruit software for prospects to trial; an offer enthusiastically taken up at the event and TrueFruit activation in Europe and Latin America has grown "massively" over the past six months, he says.

The newest addition to the Aerobotics stable is TrueFruit Grade, an app to grade the developing fruit based on blemish and colour, long before it moves across the packline. "TrueFruit Grade is specific to citrus right now, with table grapes to follow in the coming months," Treloar says.

Few surprises left at harvesting

The AI-enabled sizing of fruit by the TrueFruit app is currently possible for round fruit and berries of all types, as well as for berry sizing of table grapes. Some fruit morph as they mature, therefore special algorithms were written to account for the maturing shapes of, for example, pomegranates and cherries.

Aerobotics' Brett Agiotis sizing pomegranates with TrueFruit during ground-truths (photo: Aerobotics)

The TrueFruit app is iOS based running on an iPhone 13 Pro and upwards, partly because of its lens and processor quality and its GPS antenna accuracy. Aerobotics has enhanced the Apple iPhone's motion capture and blur capabilities to further limit image distortion when rapidly taking pictures with each of the iPhone's three cameras, exactly synchronised. With accurate fruit sizes in weekly or monthly intervals, as well as the date of full bloom and harvest windows, a growth curve is produced which becomes increasingly accurate with each growing season of use, as long as continuity of sampling is maintained, he notes.

As the user is taking photos, the app provides prompts to ensure that the photos are all crisp and usable for processing as well as their review afterwards by users, including marketing teams, to help buyers with an idea of what will probably be available. Treloar remarks that together with sizing distribution peaks and percentages, the information proves invaluable.

Another use for TrueFruit is not in-between the rows of the orchard or vineyard, but at the bins of harvested fruit. "You get a forecast from the photos in the orchard, but there's a lag between the fruit in the bin and it getting to the packhouse. Perhaps fruit was selectively picked, or perhaps it will go straight into storage, as with apples. This gives marketers a view of what's in the bin on its way to the packhouse or clarity on what's at hand when a bin only needs to be opened up months from now." Everything's under the hood and super-intuitive, he says: you can't press the wrong button.

Everything's under the hood and super-intuitive, he says: you can't press the wrong button.

"We recommend five or six trees per block, but what's the farmer capable of? A bigger sample size means greater data integrity and the accuracy gets better each year," he says; the process removes a lot of human error.

He was involved in a portion of the ground-truthing of the TrueFruit software for citrus, macadamias, avocados, stonefruit and pomegranates, recording thousands of manual caliper measurements from various instruments for comparison with the results generated by TrueFruit for the optimisation of the algorithmic models designed by the Aerobotics development team.

User interaction welcomed

New Aerobotics app users receive training (in-person training is first prize, he remarks), and thereafter keeping in contact with the tech company directly is important. The company also reviews the processed data or advises users on increasing sample sizes, as needed.

"There's a human step to the TrueFruit experience too, which is nice. We like to keep it organic. This is not just a tool." He adds: "All client feedback is logged and transparent. If any specific feedback really helped us, we let the client know how this fed into the system improving it. We prefer to keep clients involved as we advance. It is simply built into the DNA of the company."

One of Treloar's mandates is learning the goals and expectations of each client. "Clients only use from Aerobotics what they need: For example, if they tell me they want the information processed and pulled straight into their homemade system via API (application programming interface) that's fine. It's your data, you can customise your fields, filter and rank it, and consume the outputs according to your needs."

The modular nature of Aerobotics' solutions allows users that liberty. "Some customers opt for in-tree fruit sizing or bin sizing, some for both. Some opt to add drone surveys for tree and orchard insights, and some want pest trap management. And some want to drop beneficial insects via drone with SkyBugs too. Increasingly, clients are opting for several, or for all of the available services in combination."

He observes that because clients are at the outset explicitly asked what bothers them, their feedback is often rewarding and emotional.

"Quite often I hear from regular customers: 'Ken, because of not having to complete Excel sheets, I can pick up my kids from school myself'. Or: 'I'm less stressed because I know the data is accurate when I send it to my boss. It has changed my life.'"

For more information:  Ken Treloar

Ken Treloar

Aerobotics

Tel: +21 21 035 1060

Email: [email protected]

https://www.aerobotics.com/truefruit