Berrytrade is a Polish fruit company, exporting blueberries to multiple European, Middle East, and Asian countries. Sandra Stefaniak-Syguła, the co-owner of the company, shares her opinions about the ended blueberry season in Poland, notable market trends, company's investment, as well as expectations regarding the future.

Milbor: Berrytrade deals with different types of fruits. In your opinion, which product still show the biggest growth potential in the European market?

Sanda Stefaniak-Syguła (SSS): Blueberry, undoubtedly. It is extremely difficult to find another product in the fruit and vegetable category, which has received as much marketing efforts as blueberry. Talking about Polish retail chains, it is literally everywhere: on the billboards in front of the stores, in the sight of the consumer to the shop entrance or as one of the first products seen by the customer in the grocery section of the store. Its popularity is growing and that is main reason why we are focusing on blueberries.

You have 20+ years of experience in the fruit sector. Comparing to the previous years, how can you briefly describe the 2024 blueberry season in Poland?SSS: Due to the weather conditions, it was relatively short and, thus, very intensive time for growers as well as traders. At first, we had some unexpected ground frosts, and then scorching summer. These two circumstances result in lower quality of the fruits. Another quite often issue in this business are labour shortages. We struggled with this problem last months, too.

What are the greatest challenges that the blueberry sector in Middle Europe is facing now?

SSS: From my perspective, there are several issues that need to be addressed. Firstly, we need a big step forward in automatic blueberry harvesting. The solutions we have right now, they are insufficient and require some upgrades. This seems to be a priority in the light of shrinking labour force and growing costs of employment. Secondly, the strict UE standards regarding products as well as import/export rules. The inflated norms make our job harder and our business less profitable. I believe it is not only the blueberry sector's worry. Thirdly, we all struggle with climate changes and severe weather events that can ruin fruit and vegetable production.

Thinking global, which trends do you notice in the world blueberry market? How do trends determine your business model?

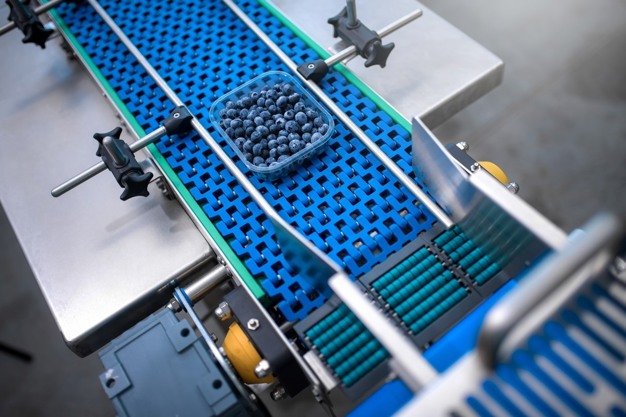

SSS: With blueberries in abundant supply worldwide and fierce global competition, finding suitable new markets is essential. However, not all markets are viable due to distance and logistical challenges. To meet demand efficiently, Berrytrade not only imports and exports blueberries but also offers service packaging near to key markets, especially for major exporters from South America and Africa. This local packaging capability is increasingly required by Polish retailers, allowing Berrytrade to provide fresher products with reduced transport expenses and improved market responsiveness.

Why did you decide to replace a competitive machine with A&B Packing Equipment filler machinery?

SSS: There were a few arguments behind this decision. We were set on top-tier service with quick response and reliable access to spare parts – Milbor PMC addressed well all these challenges. Talking about the machine itself, we needed maximum efficiency, limiting the numbers of downtimes and stoppages. Additionally, G2 Evolution treats the blueberries gently and allows us to keep prime quality of fruits we sell. Finally, it is the machine's accuracy. Every gram of product lost to unnecessary overweight has a significant financial impact for us. Having a whole-year perspective in mind, we are talking about really big money lost due to inaccurate weighing. In today's competitive global market, where margins are tighter than ever, we simply cannot afford such waste.

And which benefit have you gained thanks to implementing a new weigh & fill machine?

SSS: I would say we have great, measurable outcomes. Using G2 Evolution we can pack fruits in a more effective way (less overweight), with impressive speed and performance providing top quality of fruit handling. Better accuracy of the packing allows us to save even 2-3% on each 125g packaging. This is important because we want to develop towards distant destinations, and in the case of exports by air, there are mainly such small packaging.

Thanks to the investment, we reduced the number of staff needed to operate the packing line. Moreover, the new machine is easy to operate for our staff.

What are your opinions regarding cooperation with Milbor PMC? Do you recommend Milbor PMC to other companies?

SSS: My feedback is really positive so far. We have had one issue during the packaging process. We needed some parts to be replaced. Called the service and… 1,5 hour later the machine was running smoothly with the new parts installed. This quick time response is crucial, especially during peak season. Apart from that, I appreciate Milbor PMC for good communication, results-oriented perspective, qualified engineers and machines for testing.

For more information about Milbor PMC offer:

Maciej Chmielewski

Milbor PMC

Phone: +48 538 359 172

Email: m.chmielewski@milbor.pl

www.milborpmc.com