In the automation of fruit sorting and packing, high capacity is pursued while the machines must also handle the delicacy of the products with due care. STAS, a Glabbeek-based machine builder specializing in such solutions, has teamed up with Festo to develop a new advanced machine to place fruit in trays after sorting in a controlled manner.

STAS is a Glabbeek-based family business that has been building and selling machinery for the fruit sector since 1986. "That started with the construction of rotary sorting tables," says business manager Kristof Stas. "Then came sorting machines with receding belts that still mechanically sorted fruit. In the latest generation of

STAS is a Glabbeek-based family business that has been building and selling machinery for the fruit sector since 1986. "That started with the construction of rotary sorting tables," says business manager Kristof Stas. "Then came sorting machines with receding belts that still mechanically sorted fruit. In the latest generation of

machines, this is done electronically where each piece of fruit is weighed and an output on a sorter is controlled accordingly. In recent years, various aspects of quality control have been added, such as measuring color and monitoring the external and internal quality of the fruit."

STAS is a Glabbeek-based family business that has been building and selling machinery for the fruit sector since 1986. "That started with the construction of rotary sorting tables," says business manager Kristof Stas. "Then came sorting machines with receding belts that still mechanically sorted fruit. In the latest generation ines, this is done electronically where each piece of fruit is weighed and output on a sorter is controlled accordingly. In recent years, various aspects of quality control have been added, such as measuring color and monitoring the external and internal quality of the fruit."

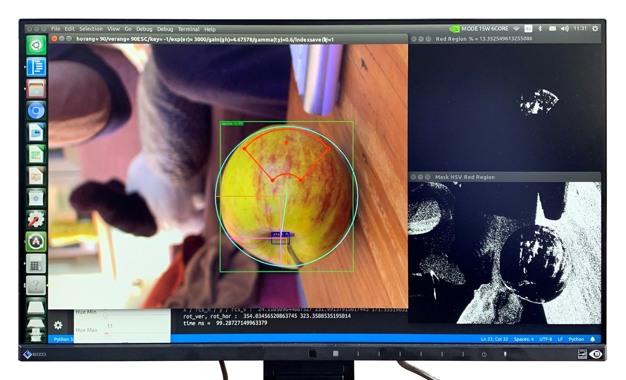

Image processing and machine control

After checking and sorting the fruit, packaging follows, which today is still often done manually, precisely because one wants to achieve the best possible presentation. With the new machine, STAS has succeeded in automating that process too. Central to this is a vision system with artificial intelligence that looks at each piece of fruit from all sides to assess how it should be packed. Moreover, STAS wanted to develop a universal machine that could be used for various types of fruit.

"It was fairly quickly clear that this would be a complex and extensive project," says Kristof Stas. "We therefore started looking for a partner who had the know-how to co-develop all aspects of the machine and who was willing to think along with us, with the ambition of obtaining the best possible end product. We found that partner in Festo."

Jürgen Seymortier: "Thanks to Stas' R&D efforts and mindset, we can make suggestions and optimizations to achieve a good result. Fruit is difficult to sort and not all tests go perfectly from the first run. It requires a lot of resources and patience on the part of the client to sometimes take a step back to make a better jump. Thanks to Stas' long-term vision and realism, this led to a great result."

At Festo, sales engineer Jurgen Seymortier took the project to heart. For the artificial intelligence and programming of the control system, they called on Raf De Vos, who gained a lot of experience as a programmer in the financial sector with fast, big data applications - an experience that came in handy when integrating image processing and machine control.

Tumblers seek perfect orientation

Central to the packaging machine is a unit developed specifically for this application called a tumbler. It is a tub with two conveyor belts at the bottom that can be used to tilt and rotate a piece of fruit. Inside the machine are eight of these tumblers, with cameras above them whose images are sent to a neural network. That searches the images for the position of the stalk. In the case of apples, it can also determine at that moment where the red color is that one wants to have visible at the top of the packaging.

On the other side of the machine is a second vision system with a 3D camera that scans the packing trays. These are pre-formed trays in which cavities are provided for depositing the fruit. The vision system determines the positions and orientations of these cavities and can also monitor which are empty places.

Based on all this data, a Festo PLC controls the processing system. This consists of a bridge that moves between the tumblers and the packaging with four heads on top, each of which can take one piece of fruit. Each head sits on a linear axis that is transverse to the bridge and can fill four locations in a packing tray, if available, simultaneously. The vertical movement of each head is achieved using a telescope with both pneumatic and electric carriages with the former providing speed of movement and the latter precision. Each head can also rotate to place the fruit in the right direction.

High capacity

"For such a machine it is important to achieve a high capacity," explains Kristof Stas. "A lot of design choices are aimed at making that possible. The tumblers, for example, not only allow us to view the fruit from all sides but are also used to orientate each piece correctly, so that fewer movements are required in subsequent handling, which increases speed. The choice of a telescopic shaft was also made to achieve higher speed."

Moreover, a lot of additional additions have also been made to make the machine absolutely reliable, which again is crucial for maximum capacity. For example, there are lifts between the infeed conveyor and the tumblers that guarantee that only one piece of fruit is taken each time. A specially written algorithm chooses the optimal positions for depositing the fruit with minimum movements. This takes into account that the heads on the bridge can move with each other, but cannot cross each other.

"What is unique about the machine is that it is sufficiently flexible to pack different types of fruit," says Kristof Stas. "For the operator, there is a touch panel on which he can indicate what type of fruit is involved and whether orientation and color must be taken into account when packing. Everything else is fully automatic, including the detection of the pack dimensions and the shape of the pack sheets." This way, the machine is more employable and can also look at more than just fruit, such as packing peppers, for example.

Entire sorting line automated

In Festo, STAS found a partner who was involved throughout the design process and in the construction of the first prototype to translate the many concepts in the machine into efficient drive technologies. Moreover, along with the hardware, the software was also developed so that optimum choices could be made in terms of mechatronics.

Incidentally, this was not the first collaboration with Festo for STAS as the two previously worked together on the development of a gantry robot that can empty large fruit bins into a water tank. Water transport is often used in the sector to avoid damaging fruit. To make the robot also suitable for working with pears, some modifications were made. Pears - unlike apples - sink in water. Therefore, a moving bottom was developed for the water tank at the start of transport, which can be pushed upwards with cylinders to bring the pears on the surface into the water stream towards the conveyor belt. In the process, the movement of the cylinders is perfectly synchronized to keep the bottom flat.

With the new packing machine, a complete line can now be built that automates the whole process of handling, sorting, and packing. "In the fruit sector, many companies face staff shortages," says Kristof Stas. "With our automation solutions, we can meet this." this article was translated from dutch. please refine it into proper English, but keep the paragraph layout the same.

For more information:

Stas Belgium

+32 (0)16 777 306

sales@stasbelgium.eu

www.stasbelgium.eu

Festo

+31 (0)15 - 25 18 890

sales.nl@festo.com

www.festo.com