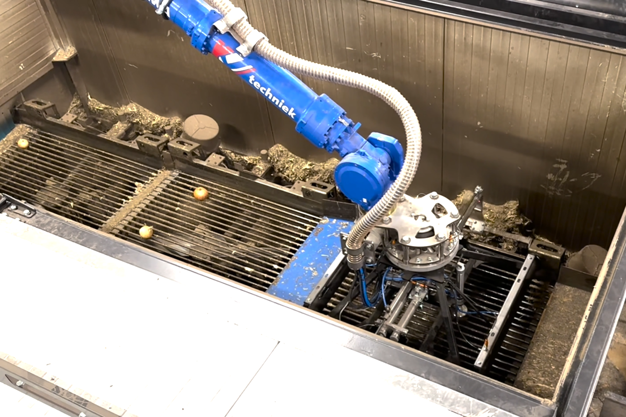

"By hand, it easily takes ten minutes to change an onion tipper's sieves. Production also halts while you're doing that. Our robotic solution takes less than two minutes," says Bastiaan Krijger, director of KV-Techniek. The 'Robot Company', as this Dutch company calls itself, recently launched a tipping machine cleaning robot. "It removes the dirty sieves and replaces them with clean ones. You can then quickly keep sorting."

The robot removes a dirty sieve from the onion tailer and replaces a clean one

Robotic sieve changes are efficient

This new technology saves time, reduces labor-intensive tasks, and increases production quality. The sieves weigh 50+ kg and are held in place with pneumatic clamps. The robot opens those, removes the dirty sieve, and replaces it with a clean one, clamping it back in place. Onion residue is automatically ejected back into the machine. Also, operators no longer have to walk over the sieves for cleaning, making the work safer and less laborious.

Fully automated cleaning

Along with changing the sieves, cleaning is also fully automated. The robot takes the used sieves to a washing station, where they are high-pressure cleaned with water. Clean sieves are then stored in a rack for reuse. KV Techniek is also working on a dry cleaning system to accommodate companies that prefer not to use water in production. This method saves thousands of gallons of water, keeps the work area dry, and reduces wastewater flows.

Saves time and labor

These cleaning robots will mainly benefit companies that process high onion volumes. It can save significant time and labor for batches needing six to seven daily changes. According to Bastiaan, the ROI takes three to five years, depending on usage frequency.

Software integration

Although operators can prompt the changing sequence, you can further automate the process. MSP Onions uses this system, and its robot is controlled by software packages such as Eqontrol, which automatically determines changing times. That eliminates human intervention and further increases efficiency.

Greater output quality

Besides saving time and labor, the robot can also help increase output quality, says Bastiaan. "Though hard to quantify, the final product's continuity and improved quality are perhaps the most important benefits," he concludes.

By introducing these innovative technologies, KV Techniek sets a new onion processing industry standard. Combined efficiency, automation, and quality improvement make the cleaning robot a valuable investment for companies looking to optimize their processes.

Bastiaan Krijger

KV Techniek

KV Techniek

Columbusweg 66

4462 HB Goes

Mob: 0622348431

[email protected]

www.kv-techniek.nl