Food freshly, the fresh produce shelf-life extension specialist, is preparing to launch pilot trials for a new solution that combines preserving quality with optimum food safety, which is likely to help prevent costly product recalls while avoiding chemical residues associated with conventional post-harvest treatments.

Ideal for a wide range of fresh-cut and whole products from carrots and potatoes through to berries, melons, and pineapples, the Food freshly Produce Wash is a two-step system that – uniquely in the produce sector – features two dipping tanks for combined post-harvest and extended shelf-life applications.

Already the recipient of two patents in the US and the EU, Food freshly, which will be highlighting the new product launch at Fruit Logistica 2025, is currently seeking interested producers or processors to participate in up to four pilot trials during the Spring months.

How it works

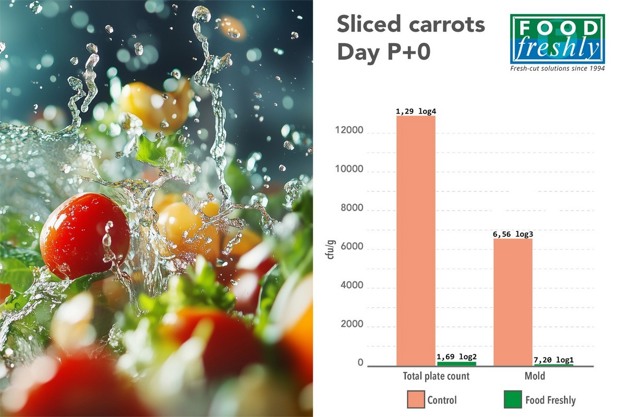

The Produce Wash works by combining two applications – post-harvest and extended shelf-life treatments – which have never previously been used in a single system, according to Benjamin Singh, director of technical sales at Food freshly. "It's a two-step wash, and both solutions work in conjunction with each other," he said. "This is a new idea and that's why we have managed to secure patents in the US and EU.

The system also overcomes some of the significant problems associated with post-harvest treatments, namely the cellular damage that can be caused to products when such solutions are applied.

"In combination, we provide a powerful tool for fresh produce companies. With the first wash, you get the removal of bacteria and fungus, while the second extends shelf-life, gives a better appearance, and prevents browning."

100% food-safe ingredients

In a break from traditional post-harvest treatments, Food freshly has made sure that all ingredients used for the Produce Wash are food-grade materials authorized by EU additive legislation and the US FDA (GRAS). "This is important because, in many countries, companies are washing products with chemicals like chlorine and peracetic acid; this may be permitted in certain countries, but they are not graded as food ingredients," said Singh.

"That is a big difference because we are only employing recognized food-grade ingredients, meaning our process doesn't leave any toxic residues behind or any of the negative aspects associated with disinfectant products such as smell, and dangerous attributes. For example, with many products, companies have to check how much they are using and whether it exceeds legal limits, whereas there are no legal restrictions on our process."

Particularly suited to larger producers and processors, Singh sees the system being effectively used in the near future as an alternative to fungicides for whole products, from pineapples to herbs.

Food freshly will exhibit at Fruit Logistica in Hall 21, Stand E-50.

For more information:

Benjamin Singh

Food Freshly

Tel: +49 52196 878715

[email protected]

www.food-freshly.eu