Forecasting customer demand, increased labor costs and shortages of workers are the everyday issues that fresh produce packers and producers are confronted with. Applying appropriate technological solutions, blueberry producers now have the ability to adapt to the requirements of their customers and fulfill orders quickly and reliably.

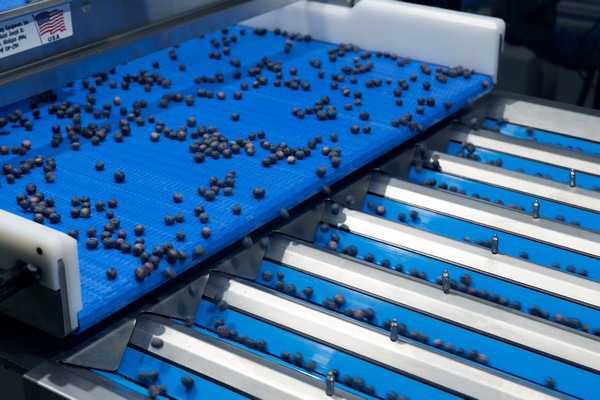

The AirJet® Blueberry Grader developed by Australian company, GP Graders, was designed to meet the growing demands of customers in a changing industry. Using an innovative approach to singulation the system allows the proper placement of blueberries onto conveyor where they are accurately sorted based on live feedback from gpVision™ cameras.

Open Software

The sorting system consists a set of three Full HD cameras per lane: shrivel, colour, and near infrared (NIR) cameras. The grader captures 30 images of each fruits’ surface, which enables a very detailed inspection from all angles of each single berry. Using the available images, the software sorts berries according to: size, softness/firmness, defects, colour, together with internal and external defects. The unique feature of the system is that it enables the user to find and reject 100% of dehydrated and shrivel fruit. The AirJet® Blueberry Grader sorts berries at the speed of up to 45 units per second per lane, providing high throughput while maintaining sorting accuracy.

The colour camera is responsible for detecting the colour of the fruit, whether it has a stem (or not) and visible defects. It enables the rejection of red, green, and underripe fruit, and is able to grade berries according to the wax bloom level. The soft camera detects berries that are shrivel, dehydrated and collapsed that happens to berries during long distance transportation. The berries are hard and firm, but the visual appearance of the berry is not appealing for the end customer. And the NIR camera detects the fruit based on its shape, hardness, and is also used to measure the diameter, or size. The software allows the produce to be separated into 5 categories of softness to firmness. Moreover the gpVision™ technology detects internal and external defects such as bruises, discoloration and dryness.

The cameras used in this machine are the highest quality - they can detect even small details, have perfect colour reproduction and high resolution. Only with a crystal clear image we are able to see defects. The solution was developed to detect all defects prevalent on the fruit without losing production efficiency.

The software was created by operators for operators, therefore it’s very simple and user-friendly. With the help of the new simple user interface (GUI) the operator can learn and operate the system in a couple of hours. Moreover, to stay ahead of the market, the software is capable to defining new defects that may occur each season due changing weather and growing conditions. Hence the open construction of the software allows it to adjust to different fruit quality and defects as well as enabling it to sort fruits according to various client’s specifications.

Hygienic design

The AirJet Blueberry Grader is designed according to strict hygiene and sanitation standards. The design of the machine is robust, but at the same time it’s easy to be washed due to its tubular construction and lack of flat surfaces on the machine. In view of the current sanitation requirements it is crucial to have a food grade machine that is easy to clean, maintain with no risk of food contamination.

The aim of engineers and designers of the AirJet® Blueberry Grader was to construct a machine that is accessible for maintenance. The machine has an open construction through which all potential problems can be readily identified. Other systems are closed with solid bodies causing major maintenance issues.

Furthermore, the design of the machine significantly reduces the time required for cleaning. The entire machine is made of stainless steel and plastic components. There are no flat surfaces where water drops can sit or water can pool. The lack of flat, horizontal surfaces allows the water to run faster after washing and also prevents fruit from accumulating. The machine also has a strong, heavy duty construction. Another point that makes cleaning easier is that all cables have been put inside stainless steel pipes.

Reduce the cost of sorting and packing blueberries

The AirJet Blueberry Grader was introduced as a new concept of the machine that is dedicated for the category sorting of blueberries and answers the dynamic market changes and increasing changing customer requirements. The high growth of blueberry consumption in Europe, together with increasing demands from retail chains results in producers having to continuously adapt to trends in order to remain competitive. An investment in new technology can significantly improve the efficiency of all production processes, reduce costs, and additionally eliminate some of the existing problems.

The AirJet Blueberry Grader was designed by GP Graders in Australia. They have been manufacturing graders for cherries and blueberries for many years in Europe, Chile and North America. Milbor PMC is the exclusive distributor of this machine in Europe. The company provides and implements high-end technology solutions as well as maintaining after-sales support in terms of service and responsiveness - service is available 24/7.