© Carolize Jansen | FreshPlaza.comTwenty years ago, Lizelle Venter took over the running of the family-owned packhouse, a space in which she literally grew up, working there during school and college holidays. She has developed an almost instinctual sense for the packhouse, difficult to convey in words, but standing her in good stead in a job where the only constant is extreme variability. "Everything that could have gone wrong so far this season has gone wrong," she calmly remarks.

© Carolize Jansen | FreshPlaza.comTwenty years ago, Lizelle Venter took over the running of the family-owned packhouse, a space in which she literally grew up, working there during school and college holidays. She has developed an almost instinctual sense for the packhouse, difficult to convey in words, but standing her in good stead in a job where the only constant is extreme variability. "Everything that could have gone wrong so far this season has gone wrong," she calmly remarks.

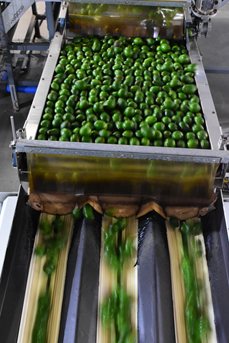

When Levubu's avocado harvest started six weeks ago, this was a crop that had already been through the wringer: the worst frost in living memory in July, followed by a fire, then heavy winds leaving marks, and in November two weeks of temperatures around 40°C ("extreme hell", she calls it, during which young trees shrivelled) even before the first rains of the season.

Since last year, Amondel has been packing avocados already in mid-January through extending its expertise and marketing acumen to Venda farmers, participants in a South African Avocado Growers' Association study group. It's a win-win: immature avocados no longer cause the super-early market to nosedive, prejudicing Levubu farmers following on their heels, with financial gains for farmers from both areas.

However, in February, the Levubu Fuerte harvest had barely started when disrupted by continuous rain, which also meant the full spray programme on Hass couldn't be carried out. Levubu Fuertes are meant to be packed away by the first week of March to make way for Hass, she explains, and it has been a rush to get the last Fuerte off the trees.

On Venter's desk are Fuerte fruit retained from earlier shipments, kept at ambient temperatures (unlike the CA containers in which they're exported), and what she's seeing doesn't please her very much. Because of rain delays, some farmers and exporters grew impatient to get the first avocados off to Europe before the price drops. Picking wet avocados (like lemons) is always a bad idea, resulting in lenticel damage and secondary anthracnose, as these retention samples show.

© Carolize Jansen | FreshPlaza.com

© Carolize Jansen | FreshPlaza.com

Increased competition between South Africa and Peru

The Fuerte crop matched their yield estimates, and packouts were satisfactory, but size was the problem. "The fruit is very small as a result of the heat in November. We barely even saw a count 16, and the local market quickly came under pressure on the 20s and 24s. We could only export up to count 22 on greenskins, and all I'm sitting with are 24s, which nobody wants. Not even in bags," she says. "It was challenging."

They knew to expect lower Hass volumes, even a decrease of 20% to 25%, she says, but they were at least aiming for packouts averaging 65% to 70%. "I didn't realise the packout would be as low as it is: an export packout of 40% of which 50% are jumble sizes that can only be exported for guacamole.

"It means there's very little coming over the line for fresh exports. We registered to send to China and India just in case, but I don't think we will: we don't even have enough fruit for the EU."

The sizing distribution is peaking on 24s ("the unwanted child no-one wants", she calls this calibre) and an oversupply of jumbles. Retail looks for calibres 18 to 26, and that's where there's going to be a shortage.

© Carolize Jansen | FreshPlaza.com

© Carolize Jansen | FreshPlaza.com

It's been difficult to pack full containers of the larger counts that Russia prefers. "I like packing for Russia. The price is stable, and it's fixed: when you load here, you know what you'll be getting for the fruit."

The problem this season, she explains, is that Peru also has small fruit as their orchards get older. "Usually Peru traded in the band of 14s to 22s, with some overlap with us on 22s and 24s, but now they too are tending more towards the jumble side as a result of the age of their orchards."

Locally, Amondel is a preferred supplier to retailers, avocado ripeners, and food processors, but it's not to the detriment of South Africa's municipal markets. Four times a year, she loads what she calls "the milk train", taking avocados round to smaller municipal markets from southern Gauteng, North West Province, and into the Free State. In this way, she takes pressure off the main Gauteng markets, she says, while whetting an appetite for Levubu's finest.

When the main avocado crop has been packed, she turns her attention to the guavas grown on the family farm Amana Boerdery: she manipulates it into ripening from May to October to avoid an overlap with avocados, making them the only guava supplier in South Africa at that period before an encore of Lamb Hass avocados in August.

© Carolize Jansen | FreshPlaza.com Green boxes are for domestic distribution, red boxes are exported

© Carolize Jansen | FreshPlaza.com Green boxes are for domestic distribution, red boxes are exported

Keeping the packhouse compliant

Before the late Lamb Hass could roll over the packline last year, the packhouse had to be deep cleaned because the routine postharvest fungicide into which avocados used to be dipped is no longer allowed.

Venter had the foresight to start the process well in advance, and as well she did: in the end it took them three months to rid the packline of all traces of prochloraz, an endocrine disrupter.

Stainless steel components could be treated with acid, but cleaning other parts of the packline was an arduous process. "We stripped the whole line, scrubbed it with tiny toothbrushes, ran fruit over it, did some swabs – and still picked up residues. So we did it all over again. After the second wash, I realised the brushes were never going to be cleaned, so they were replaced. And those white belts – you just can't get the residues out of it. Every single cup of the thousands in the cup sizers had to be taken out and scrubbed."

An individual with more energy, she says, than the average person, Muller admits that she rarely takes a holiday, preferring to keep a steady hand on the tiller.

© Carolize Jansen | FreshPlaza.com Lizelle Venter

© Carolize Jansen | FreshPlaza.com Lizelle Venter

For more information:

Lizelle Venter

Amana Boerdery & Amondel Pakkers

Tel: +27 82 853 8779

Email: lizelle@amanabdy.co.za