We've been hearing a lot lately about artificial intelligence. The ability of computers to mimic human thought and decision-making, to automate tasks that traditionally required human intelligence, has stirred up all sorts of sensational news stories. In confirmation of this technology's increasing importance, TOMRA Food has just launched two new AI-powered sorting and grading solutions. Two recent product launches have shown how AI is changing food processing. James French, Head of Innovation at TOMRA Fresh Food, part of TOMRA Food, explains how AI is already adding value and why its importance will grow.

"One of those solutions, the all-new TOMRA Neon, pre-grades machine-harvested blueberries for the fresh market. The other, the new-generation Spectrim X series, leverages Deep Learning for unmatched sorting and grading precision of fruit. These machines are just the start of a revolution which will make the production of fresh and processed foods more efficient and profitable," says French.

Many benefits for processors

"There's no denying that AI-driven automation will be deployed to tasks currently handled manually, including some of the routine tasks at food processors and packhouses," states French.

TOMRA Food has been utilizing artificial intelligence since 2019 to make sorting and grading solutions more accurate than traditional techniques. The deployment of AI powered technology in the food production industry will continue to accelerate into the future.

Make no mistake: AI is bringing a big technological shift that businesses will have to keep up with to remain competitive.

AI and Deep Learning in action

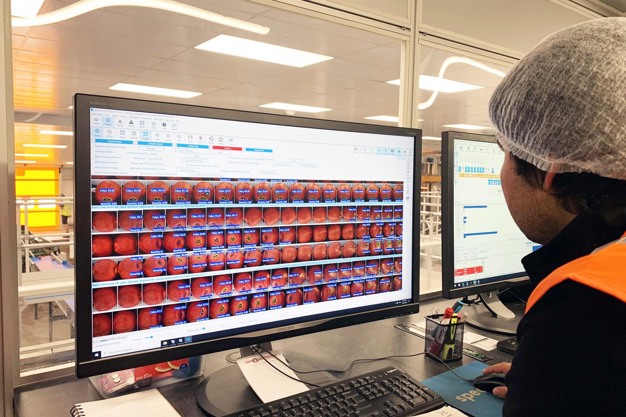

Deep Learning is an AI method which uses pre-trained models to teach computers how to process data, such as complex patterns in photos. The newly-launched Spectrim X series grading platform is a great example of this. Developed by a team of industry-leading scientists, engineers, researchers, and experts, Spectrim X integrates the latest development of TOMRA’s LUCAi™ Deep Learning technology.

The Spectrim X series grading platform is equipped with LUCAi™ Engine Software, computing hardware, and pre-trained models which achieve unprecedented grading precision. More packing operations can now be achieved without manual intervention, targeting thresholds more closely and all while minimizing fruit loss.

AI also powers the new TOMRA Neon, to pre-grade blueberries. Automated blueberry harvesting is faster and less costly than manual harvesting but brings challenges in the form of unwanted debris and fruit clusters to fresh fruit processing and packing lines. To address these challenges, TOMRA Neon accepts and rejects fruit before transferring it directly onto TOMRA’s KATO260 optical sorter and grader. It is by using AI that TOMRA Neon is able to identify, differentiate, and remove unwanted clusters, undersize fruit, and unripe fruit. This optimizes optical grader efficiency by removing more than 95% of clusters and more than 90% of unwanted green and red berries.

For more information:

Michelle Haynes

TOMRA Food

Tel.: +64 21 377 141

Email: michelle.haynes@tomra.com