Ready-made salads have been in demand for quite a few years and, the more they are colorful, the more they are appealing. Increasingly fast and dynamic lifestyles, after all, boost the demand for produce that meets the needs of those looking for ready-to-eat solutions maybe for a quick lunch or for health reasons. This is one of the reasons that push the producers of ready-to-eat salads to add red,yellow or a mix of tomatoes to their trays.

Virginia Cascella.

Virginia Cascella.

"Consumption increases in the summer and our company has actively answered the market's significant demand. We have just completed a new project that saw our MTP cutter, perfect for cutting tomatoes in half or in quarters for the fresh-cut range, integrated with a washing system," explains Virginia Cascella, export manager at PND, a global leader in the production of processing machinery.

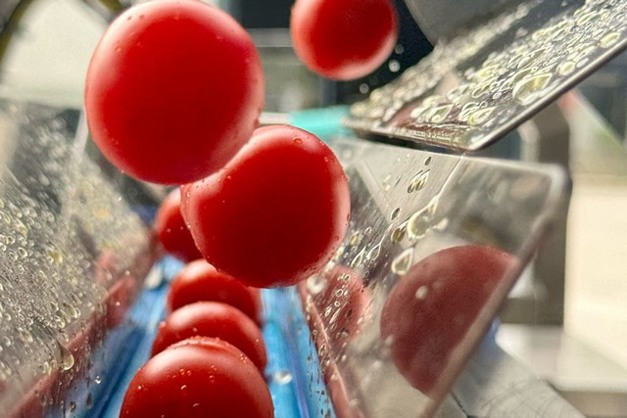

Washing phase.

Washing phase.

But what is the advantage of using PND machines? "They are quick, as they can process around 200 kg/hour, and they are also very safe, as they are developed to meet all safety standards. Of course, they are also innovative as loading is automatic: the produce is tilted into the washing tank and then an elevator takes it to a conveyor that aligns it and transfers it to the cutting station."

Finished product.

Finished product.

"The cutting unit is made up of 4 rotating circular blades which enable the cutting of the produce into quarters. A mechanical lever system moves two blades to cut tomatoes in half instead. Lastly, a conveyor under the cutting station collects the cut tomatoes. We are expecting great success for what has turned into a well-tested prototype produced for a single client, as interest has already piqued throughout Europe."

The machine can process tomatoes of various grades between Ø 25 and 40 mm, and is easy to move because it is equipped with wheels which, upon request, can be replaced by adjustable feet.

The machine can process tomatoes of various grades between Ø 25 and 40 mm, and is easy to move because it is equipped with wheels which, upon request, can be replaced by adjustable feet.

"Our strength is that we know how to provide answers to our clients with ad hoc processing lines and, once again, this machine is the perfect example. A vision that pays attention to technological performance, perfectly adapted to the needs of those requiring the machine."

"Choosing us means receiving personalized, quick and efficient assistance on a global scale. Discover the PND world by visiting our website, which features a catalog with the different lines and machines available, as well as a list of all national and international fairs."

For more information:

Virginia Cascella

PND - Fruit Processing Machinery![]()

Via Brancaccio, 11

84018 Scafati (SA) – Italy

+39 0818509368

info@pndsrl.it

www.pndsrl.it