"The Bio Ferrarini farm was established in 1997, driven by my passion for agriculture and my sister Monica's dedication to producing top-quality, sustainable, and healthy food. We represent the fifth generation of farmers," says Andrea Ferrarini, the company's sales and production manager. "We are located in the municipality of Mirandola, in the lowlands of Modena and the land of the Pico, in the Emilia Romagna region, in an area highly suited to fruit and vegetable production. We have always embraced the principles of organic farming, operating with full respect for the environment and nature. Transparency and genuineness are the cornerstones of our company mission. In 2017, we transitioned to biodynamic farming. Today, we manage over 150 hectares dedicated entirely to organic-biodynamic cultivation. We've set aside about 10% of this area to actively promote biodiversity."

Giovanni Buccheri, Demeter Italia's director, and Andrea Ferrarini, Bio Ferrarini's sales and production manager at Sana Food 2025

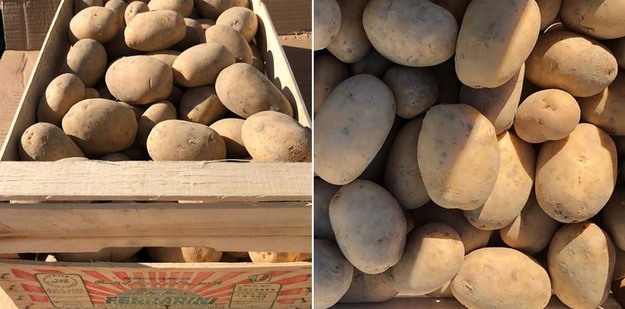

"My sister and I started an organic cultivation project between 1995 and 1996. At the time, this method was not yet widespread. We began with about ten hectares and went through the whole conversion process," explains Ferrarini. "We found a partner in the large-scale distribution, Natura Sì, who supported us. Our green beans, a crop our father had experience with, were our flagship product. Today, our production also includes potatoes, onions, garlic, shallots, melons, tomatoes, and watermelons. We're also carrying out an interesting project with organic sugar beets, and we grow soybeans, durum wheat, and soft wheat."

When asked about his life, Ferrarini confidently shares an anecdote about his current job: "As a child, I spent a lot of time in the countryside with my father. However, around the age of 12-13, I started to develop intolerances to certain active ingredients. These problems prompted me to change my path. After graduating in electrical engineering and completing my military service, I spent three years at the fruit and vegetable market in Bologna. This experience enriched me greatly and allowed me to see the other side of production. It was during this time that I discovered new possibilities related to alternative methods of cultivation."

The company's commitment to excellence is further underscored by its additional certifications, in addition to organic certification: Biosuisse, Naturland, GlobalGAP, and GRASP. Last but not least, it holds the Demeter certification. "We support good agricultural practices, and we also support social practices. We guarantee our workers constant health and safety," says Ferrarini.

"We're actively marketing our products in countries like Switzerland, Germany, and France. Switzerland has been a reference point for us. We've identified key differences between Italian and European mindsets, particularly concerning consumer information. In other countries, farmers' associations effectively raise awareness. I firmly believe that, with the right information, consumers can make informed choices. If they don't receive adequate information, they struggle to make decisions. However, once they have a better understanding of the work that goes into certain farming practices, they are in a better position to make an informed choice."

Going against the tide for a more sustainable production cycle

"When I started this adventure with my sister, my father had a rather traditional mentality. The idea of practicing green manure on our clay soils was revolutionary for him. We've always used 25-horsepower tractors to respect the soil because we believe it retains memories. I knew it was crucial to introduce green manure, keeping the soil active even in winter, contrary to my grandfather's and father's belief that the land should recover. Initially, my father was skeptical and against it, but everything changed when he saw the results in spring: the green manure had absorbed the excess moisture, and the soil was in excellent condition. From that point on, he began to trust my decisions. It was challenging, but the results spoke for themselves," asserts Ferrarini.

"To grow a farm, it is essential to have partners who believe in you and support you. We've been blessed with a short supply chain and a direct and transparent relationship. We're committed to biodynamics and the circularity of the farm, striving to minimize dependence on external resources like organic fertilizers. This has required sacrifices, like starting a breeding farm to better use internal resources, but it's a crucial step for a more sustainable production cycle."

"Our ancestors have taught us that experience is also built through mistakes. I've made many mistakes, but they've all been valuable lessons. I am setting an example for young people, and I trust them to make good decisions. Our work is not just a business, it's about passion. Adversity, like natural disasters, should drive us on, not down. We must therefore inspire young people, and allow them to live with authenticity and passion in whatever they do. Our responsibility should not be limited to focusing solely on business interests. While ensuring a livelihood is essential, I firmly believe in the viability of sustainable and profitable agriculture. This is what I will pass on to the next generations."

Not only fresh but also processed products

"Our processed products are born from a strong conviction, that is, no waste. We are committed to breathing new life into every ingredient that might otherwise go to waste. Food waste is a loss of food and resources, including soil, water, the environment, and money. Our shelled garlic project was born out of this commitment. We've created a new product that's both innovative and sustainable. Its packaging is recyclable, and it's made from materials that can be recycled. We meticulously select each clove and package it in a dispenser box, making it convenient for storage in the fridge. This innovative approach has given the product new life. One clove is all it takes to discard an entire head of garlic. We often end up with below-market yields. This results in a 100% waste of the reference, amounting to a 5% loss."

The same approach has been used for melons and watermelons. "While green beans and other produce can be given a second life through animal feed, melons and watermelons have had to undergo a slow dehydration process that takes about three weeks. This process reduces the original weight of the product to 5 percent. This has led us to the idea of creating a snack product for the younger generation, which we call 'Bibi Bio'. This project involves the use of cereals, fruit (dehydrated melon and watermelon), and sourdough, developed in collaboration with friends who are experts in baking," concludes Ferrarini.

For more information: Andrea Ferrarini - Sales and production manager

Andrea Ferrarini - Sales and production manager

+39 348 7043694

andrea@bioferrarini.com

Bio Ferrarini / Az. Agr. Ferrarini Monica

Via Guagnellina 5

41037 Quarantoli di Mirandola (MO) - Italy

www.bioferrarini.com